Sand Casting

What Is Sand Casting

Sand casting refers to a casting method in which castings are produced in sand molds. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting methods. Because the modeling materials used in sand casting are cheap and easy to obtain, and the molds are easy to manufacture, they can adapt to single-piece production, batch production and mass production of castings. For a long time, it has been the basic process in casting production.

Clay Wet Sand

Clay and appropriate amount of water are used as the main binder in molding sand. After the sand is prepared, it is directly assembled and poured in wet state. Wet sand casting has a long history and wide application. The strength of wet sand depends on the clay slurry formed by mixing clay and water in a certain proportion. Once the molding sand is mixed, it has a certain strength. After being compacted into a sand mold, it can meet the requirements of molding and pouring. Therefore, the clay content and water content in the molding sand are very important process factors.

A casting method that uses molding sand and core sand as molding materials to create cavities, and fills the cavities with liquid metal under gravity to produce castings. Through sand casting, steel and most non-ferrous alloy castings can be produced. Because the molding materials used in sand casting are cheap and easy to obtain, and the molds are easy to manufacture, it is suitable for single-piece production, batch production and mass production. For a long time, it has been the basic process in casting production.

The cavity used in sand casting is generally composed of external sand mold and core. To improve the surface quality of castings, a layer of coating is usually applied to the surface of sand molds and cores. The main components of the coating are powdered materials with high refractoriness and good chemical stability, and binders. In addition, carriers (water or other solvents) and various additives are added to facilitate coating.

The advantages of clay wet sand casting are:

- Clay resources are abundant and inexpensive.

- Most of the used clay wet sand can be recycled after proper sand treatment.

- The cycle of manufacturing cavities is short and work efficiency is high.

- The mixed molding sand can be used for a long time.

- After the sand mold is compacted, it can still withstand certain deformation without being damaged, which is very beneficial for mold release and core placement.

The disadvantages are:

- When mixing sand, the sticky clay slurry needs to be coated on the surface of sand particles, requiring high-power sand mixing equipment with kneading action, otherwise good quality sand cannot be obtained.

- Due to the high strength of the molding sand after mixing, the sand is not easy to flow and compact during molding. Manual molding is laborious and requires certain skills, while machine molding equipment is complex and large.

- The cavity has low rigidity and poor dimensional accuracy of castings.

- Castings are prone to sand washing, sand inclusion and porosity defects.

The wet water content of clay dry sand cavity is slightly higher than that of the sand used to produce this cavity.

Clay sand core is a simple core made of clay sand.

Dry Clay Sand

The wet water content of the molding sand used to make this cavity is slightly higher than that of wet molding sand. After the sand cavity is made, fire-resistant coating should be applied to the cavity surface, then put into the oven for drying, and after cooling, it can be assembled and poured. Drying clay sand cavity takes a long time, consumes a lot of fuel, and the sand cavity is prone to deformation during drying, affecting the accuracy of castings. Clay dry sand cavity is generally used to make steel castings and larger iron castings. Due to the widespread adoption of chemical hardening sand, dry sand molds tend to be phased out.

Chemical Hardening Sand

The molding sand used for this type of cavity is called chemical hardening sand. The binder is generally a substance that can polymerize into a three-dimensional structure under the action of hardener, commonly using various synthetic resins and water glass. There are basically 3 ways of chemical hardening.

- Self-hardening:Binder and hardener are added simultaneously during sand mixing. After the cavity or core is made, the binder reacts under the action of hardener, causing the cavity or core to self-harden. Self-hardening method is mainly used for molding, but also for manufacturing larger cores or producing small batch cores.

- Aerosol Hardening:During sand mixing, binder and other auxiliary additives are added first, without adding hardener. After molding or core making is completed, gaseous hardener or liquid hardener atomized in gas carrier is blown in, dispersing it in the cavity or core to harden the cavity. Aerosol hardening method is mainly used for core making, and sometimes also for making small sand cavities.

- Heat Hardening:During sand mixing, binder and latent hardener that does not work at room temperature are added. After the cavity or core is made, heating is performed. At this time, the latent hardener reacts with certain components in the binder to generate effective hardener that can harden the binder, thus hardening the cavity or core. Heat hardening method is mainly used for core making, and also for making small thin-shell sand cavities.

The History Of Minghe Sand Casting Workshop

Minghe Sand casting workshop was added in 2016 with the addition of a coastal sand mixer continuous sand mixer. Sand casting is a great compliment to the Rubber Plaster Mold, process the company was founded on. Sand casting currently makes up about half of our foundry business.

In 2016, Minghe Casting greatly expanded the sand casting line with the addition of a larger continuous sand mixer with dual hopper, automated controls, and mechanical reclaim. This allows Minghe Casting to move from just low quantity high quality to production quantities, while still maintaining the high quality demanded by the market place. The investment also represents the commitment of Prototype Casting to minimize its footprint for consuming natural resources, specifically the silica sand used in sand casting. Because of secondary markets for reclaimed sand, and the ability to reuse 80% of the sand in the process, the waste of sand to landfills will be completely eliminated!!!

Minghe sand casting workshop is about 8000 square meters. Whatever your casting project is small or big, we can give you good lead time and good quality. In our foundry, more than 60% Cast Aluminum parts are exported. So we have much experience for your projects.

Benefits of Sand Casting Process

The functions of sand casting can be summarized as follows:

- Sand casting wear-resistant parts are still quite common in China, such as jaw plates, high chromium hammers, crushing walls, rolling mortar walls, etc. In crushers, these are relatively large wear-resistant castings with low precision requirements. Especially for jaw plates, the finished product almost does not need lathe grinding. Crushing walls, slurry rolling walls, roller skins, etc., only need lathe grinding, which is especially suitable for sand casting. The durability of sand casting wear-resistant parts such as jaw plates, high chromium hammers, crushing walls, rolling mortar walls, and roller skins is more than 20% higher than products manufactured by other methods such as lost wax casting.

- Sand casting is a casting process. The molds used in sand casting generally consist of external sand molds and cores. Due to the low cost and easy availability of materials used for sand molds, and simple mold manufacturing, it is suitable for single-piece production, batch production, and mass production of castings. It has long been the basic process of casting production. Currently, in international casting production, 60-70% of castings use sand molds for production, and about 70% use clay sand molds for production.

- Low cost

- Simple production process

- Short production cycle

- Therefore, automobile engine blocks, cylinder heads, crankshafts, and other castings are all produced using clay wet sand process. When wet sand cannot meet the requirements, dry sand molds or other sand molds can be considered. Castings made with clay wet sand range from a few kilograms to dozens of kilograms, while castings made with dry clay can reach several tons.

Minghe Hardware Sand Casting Production Process

The basic steps of Minghe Casting's sand casting process are as follows:

- Sand Mixing Stage:Prepare molding sand and core sand for molding, generally using a sand mixer to mix old patterns with an appropriate amount of clay.

- Modeling Stage:Make molds and core boxes according to part drawings. Generally, wooden patterns can be used for single pieces, plastic or metal patterns (commonly known as iron or steel patterns) for batch production, and pattern plates can be made for large castings. Now molds are basically processed by engraving machines, so the production cycle is greatly shortened, and mold making generally takes 2-10 days.

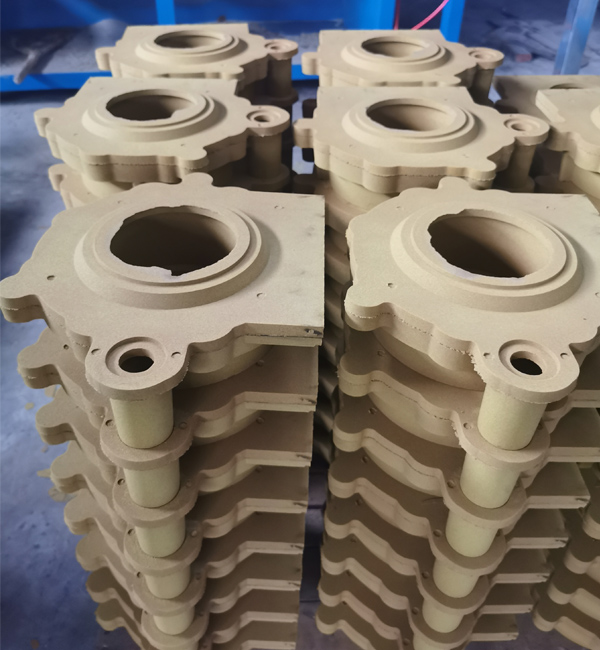

- Molding (Core Making) Stage:Includes molding (forming casting cavities with molding sand), core making (forming the internal shape of castings), and mold assembly (placing cores into cavities and closing upper and lower boxes). Molding is a key link in casting.

- Smelting Stage:According to the required metal composition, prepare chemical composition, select appropriate smelting furnace to melt alloy materials, and form qualified liquid metal (including qualified composition and qualified temperature). Smelting generally uses cupola furnaces or electric furnaces (due to environmental protection requirements, cupola furnaces are basically prohibited now, basically using electric furnaces).

- Pouring Stage:Use a ladle to pour the molten iron from the electric furnace into the prepared cavity. Need to pay attention to the speed of iron water pouring to make the iron water fill the entire cavity. In addition, pouring molten iron is quite dangerous, pay attention to safety!

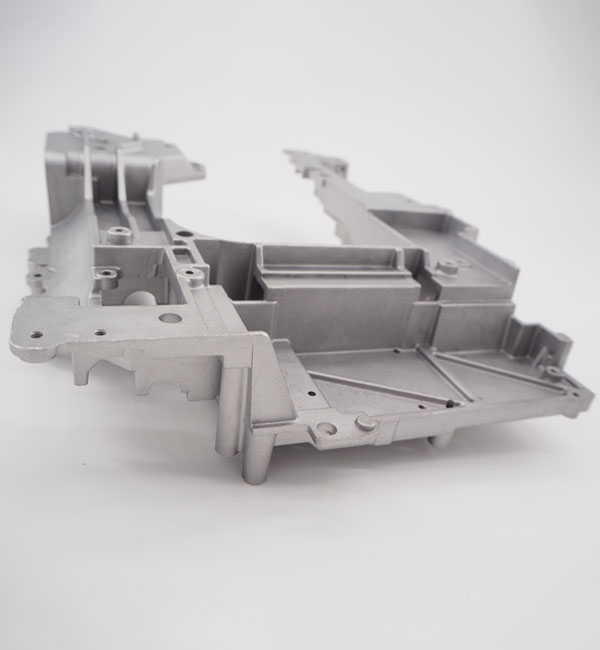

- Cleaning Stage:After pouring, wait for the metal to solidify, use a hammer to remove the gating system and shake off the sand on the casting, then use a shot blasting machine for shot blasting to make the casting surface look very clean! After inspection, castings with non-strict requirements can basically be shipped.

- Casting Processing:For some castings with special requirements or that cannot meet requirements, simple processing may be needed. Generally use grinding wheels or grinding machines for processing and polishing to remove burrs and make castings smoother.

- Casting Inspection:Casting inspection is usually done during cleaning or processing, and unqualified products are usually found. However, some castings have individual requirements that need to be inspected again. For example, some castings require a 5cm shaft to be inserted in the center hole, so you need to try with a 5cm shaft.

| Mold Development And Design ▶ |

| Sand Mixing Stage ▶ |

| Lost Wax Inspection ▶ |

| Wax Tree Assembly ▶ |

| Silica Sol Shell ▶ |

| Water Glass Reinforcement ▶ |

| Steam Dewaxing ▶ |

| Baking-Pouring ▶ |

Minghe Sand Casting Case Studies

Minghe Casting provides casting services from design to realization, capable of small to large batch production of die castings, sand castings, precision castings, metal castings, lost wax castings, etc.

View More Casting Case Studies >>>

Choose The Best Sand Casting Supplier

Currently, our sand castings are exported to the United States, Canada, Australia, the United Kingdom, Germany, France, South Africa, and other parts of the world. We have passed ISO9001-2015 certification and obtained SGS certification.

Our custom sand casting services provide durable and cost-effective castings that meet your specifications in automotive, medical, aerospace, electronics, food, construction, security, marine, and other industries. Quickly send inquiries or submit drawings to get free quotes in the shortest time. Contact us or email sales@hmminghe.com to learn how our personnel, equipment, and tooling can bring the best quality and optimal prices to your sand casting project.

Our Casting Services Include:

Minghe Casting provides services including sand casting, metal casting, precision casting, lost wax casting, etc.

Sand Casting

Sand CastingSand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold CastingPermanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

Investment CastingThe biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost Foam CastingLost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

Die Casting

Die CastingDie casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal CastingCentrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure CastingLow Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.