Inconel 718 Machining

What is Inconel 718 Machining

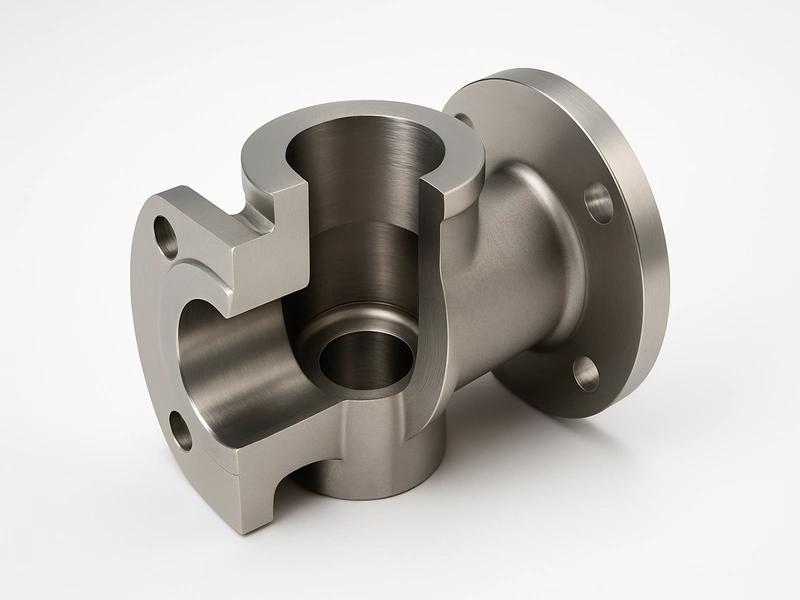

Inconel 718 machining is an advanced manufacturing process specializing in this high-performance superalloy. This nickel-chromium based superalloy maintains exceptional strength and corrosion resistance at temperatures up to 704°C (1300°F), making it crucial for critical aerospace and industrial applications.

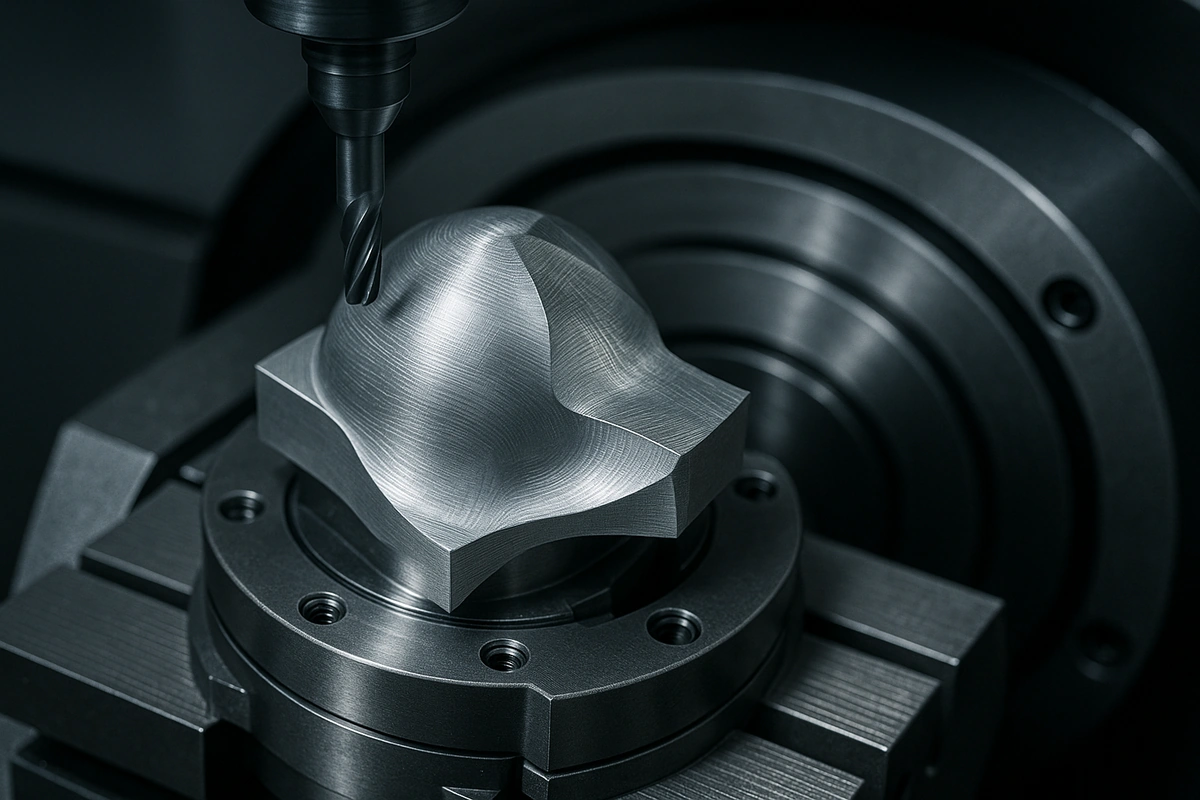

Our state-of-the-art CNC machining centers, combined with decades of expertise, enable us to produce complex components with superior precision. We specialize in both prototype development and high-volume production, serving aerospace, power generation, oil & gas, and chemical processing industries.

Advanced Manufacturing Capabilities

Our facility features the latest 5-axis CNC machining centers capable of achieving exceptional precision: • Dimensional Tolerance: ±0.005mm • Surface Roughness: Ra 0.2-0.8μm • Maximum Workpiece Size: φ800mm × 1000mm • Complex Geometry Processing: Deep cavities, curved surfaces, and precision holes

Specialized Process Control

We employ advanced process control systems specifically optimized for Inconel 718: • Proprietary cutting parameter optimization • Real-time temperature monitoring • High-pressure cooling technology • In-process inspection system • Specialized tool life management

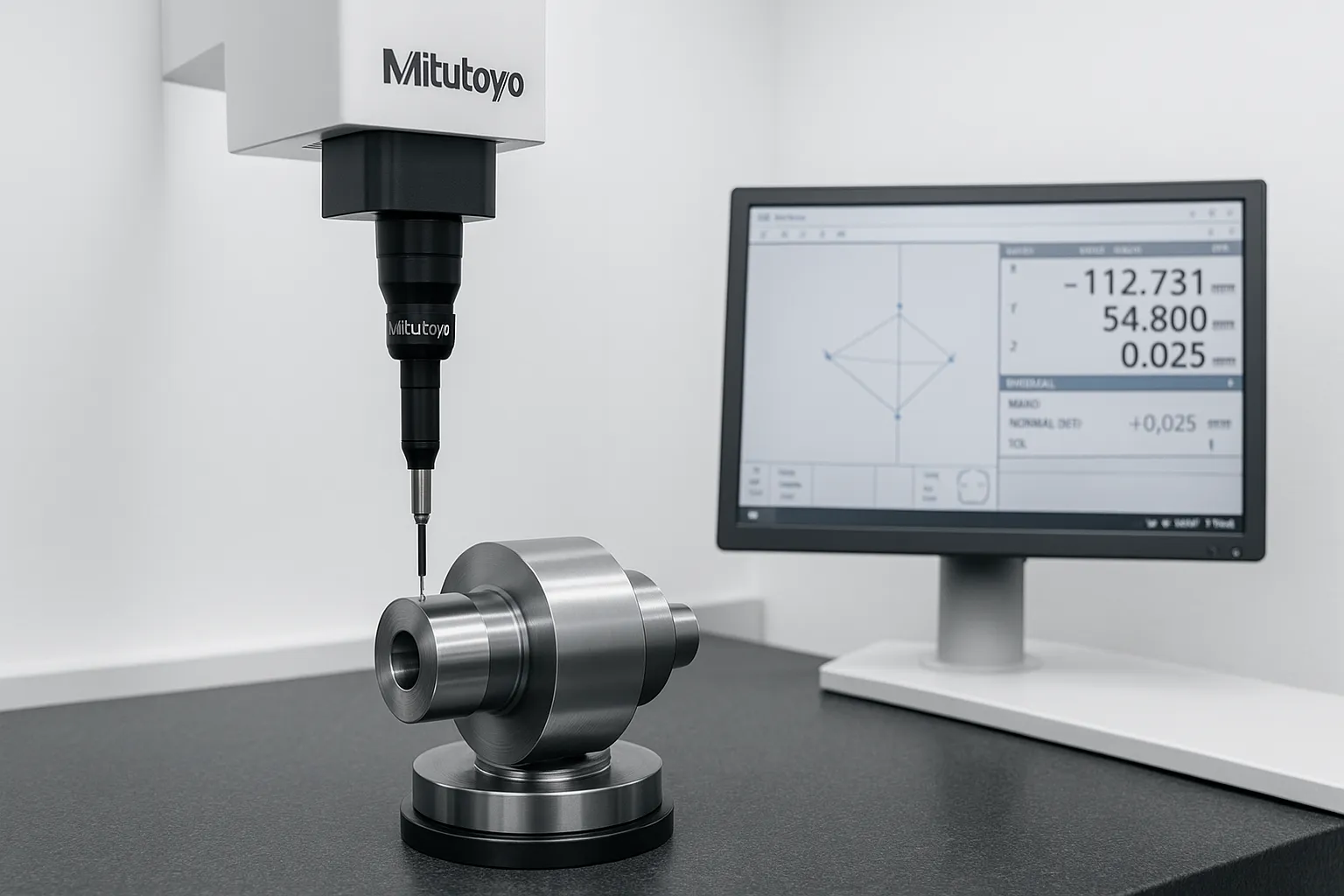

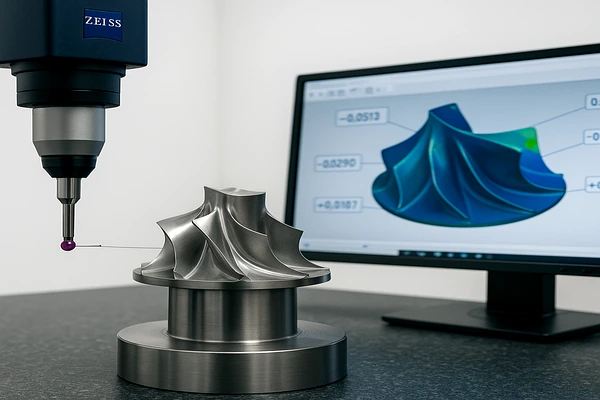

Comprehensive Quality Assurance

Our quality management system meets the highest industry standards: • AS9100D Aerospace Certification • ISO 9001:2015 Quality System • CMM Dimensional Inspection • Material Composition Analysis • Hardness and Metallographic Testing

Industry Applications

We specialize in manufacturing critical components for: • Aerospace: Engine turbine blades, compressor components, combustion chambers • Power Generation: Gas turbine parts, high-pressure valve components • Oil & Gas: Pump components, high-pressure reactor parts • Chemical Processing: Heat exchanger components, reaction vessel parts

Technical Expertise

Our technical capabilities ensure optimal machining results:

- Advanced cutting strategies for work hardening control

- Optimized machining parameters for different feature types

- Specialized carbide and ceramic tooling solutions

- Advanced cooling and lubrication systems

- Comprehensive in-process monitoring

Complete Service Package

We provide end-to-end support for your Inconel 718 machining needs:

- Design optimization for manufacturability

- Material sourcing and certification

- Prototype development

- Production scaling

- Quality documentation

- Global logistics support

With over 25 years of experience in Inconel 718 machining, our facility combines advanced technology, skilled expertise, and rigorous quality control to deliver exceptional results. From initial consultation through final delivery, we ensure your components meet or exceed all specifications and performance requirements.

Our Inconel 718 Precision Machining Process

As a professional Inconel 718 machining specialist, we provide high-precision CNC machining services for aerospace, power generation, and industrial applications. With advanced equipment and experienced engineers, we ensure superior quality for all Inconel 718 components. Our comprehensive machining process includes:

- Technical Consultation: Discuss your requirements, material specifications, and provide professional advice.

- Quote & Planning: Provide detailed quotation and customize machining solution based on your drawings or 3D models.

- Engineering Review: Our expert engineers analyze the design for manufacturability and optimize machining strategies.

- Contract Confirmation: Sign agreement and confirm technical specifications, tolerances, and quality requirements.

- Programming & Setup: Create detailed CNC programs and prepare optimal cutting tools for Inconel 718.

- First Article Production: Machine first piece for inspection and customer approval.

- Quality Inspection: Conduct precise measurements using CMM and other advanced inspection equipment.

- Batch Production: Begin volume production after first article approval.

- Surface Treatment: Perform required surface finishing and treatments as specified.

- Final Inspection: 100% quality check on critical dimensions and surface requirements.

- Documentation: Provide material certificates, inspection reports, and quality documentation.

- Delivery: Package and deliver finished parts with complete quality records.

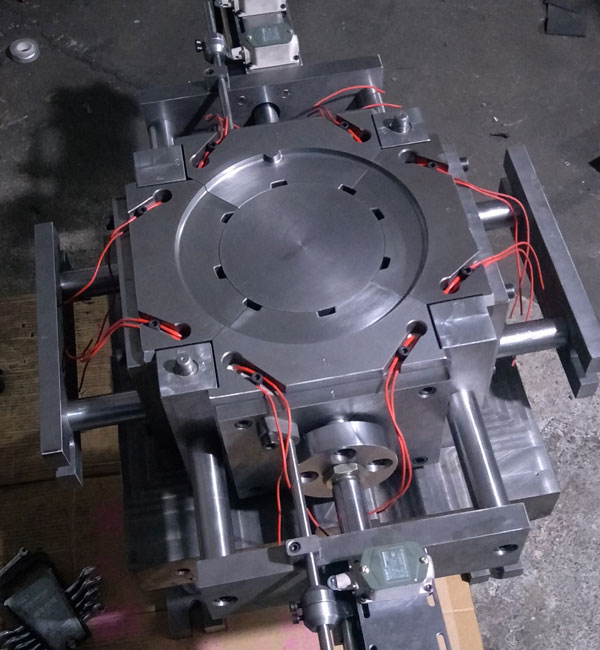

Advanced Production Facilities for Inconel 718 Machining

Our facility is equipped with state-of-the-art CNC machining centers and precision measurement equipment specifically optimized for Inconel 718 processing. Our experienced engineers provide comprehensive support throughout the entire process - from initial design review to final inspection. We maintain constant communication with customers during programming, machining, quality control, and delivery phases to ensure all specifications are met.

| CNC Machining Equipment Display ▶ |

| Precision Parts Manufacturing Process ▶ |

| Quality Control Process ▶ |

| Parts Surface Treatment ▶ |

| Advanced Manufacturing Facility ▶ |

| High-Precision Machining Process ▶ |

| Final Quality Inspection ▶ |

| Professional Parts Packaging ▶ |

Successful Cases of Inconel 718 Precision Machining

Our advanced Inconel 718 machining capabilities have been proven through numerous successful projects in aerospace, power generation, and industrial applications. From complex turbine components to precision valve parts, we consistently deliver high-quality results that meet or exceed industry standards.

View More Inconel 718 Machining Cases >>>

Why Choose Our Inconel 718 Machining Services

With over 25 years of experience in precision machining, we serve clients across North America, Europe, and Asia. Our facility is AS9100D and ISO9001:2015 certified, equipped with advanced 5-axis CNC machines and comprehensive testing capabilities.

Our expertise in Inconel 718 machining, combined with state-of-the-art equipment and rigorous quality control, ensures exceptional results for every project. Contact us at for a detailed quote and discover how our precision machining capabilities can meet your specific requirements.

We Provide Casting Services Include:

Minghe Casting services working with sand casting、metal casting 、investment casting lost foam casting, and more.

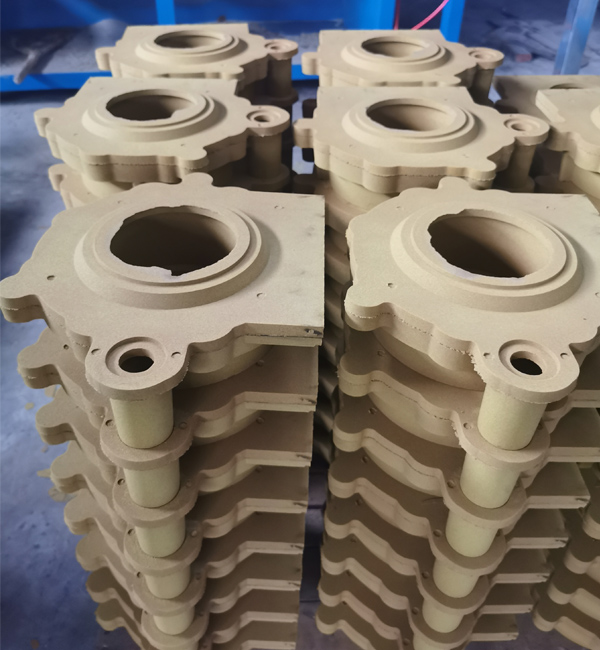

Sand Casting

Sand CastingSand Casting is a traditional casting process that uses sand as the main modeling material to make molds. Gravity casting is generally used for sand molds, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, small pieces, large pieces, simple pieces, complex pieces, single pieces, and large quantities can be used.

Permanent Mold Casting

Permanent Mold CastingPermanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface, but also have higher strength than sand castings and are less likely to be damaged when the same molten metal is poured. Therefore, in the mass production of medium and small non-ferrous metal castings, as long as the melting point of the casting material is not too high, metal casting is generally preferred.

Investment Casting

Investment CastingThe biggest advantage of investment casting is that because investment castings have high dimensional accuracy and surface finish, they can reduce machining work, but leave a little machining allowance on the parts with higher requirements. It can be seen that the use of investment casting method can save a lot of machine tool equipment and processing man-hours, and greatly save metal raw materials.

Lost Foam Casting

Lost Foam CastingLost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. After brushing and drying refractory coatings, they are buried in dry quartz sand for vibration modeling, and poured under negative pressure to gasify the model. The liquid metal occupies the position of the model and forms a new casting method after solidification and cooling.

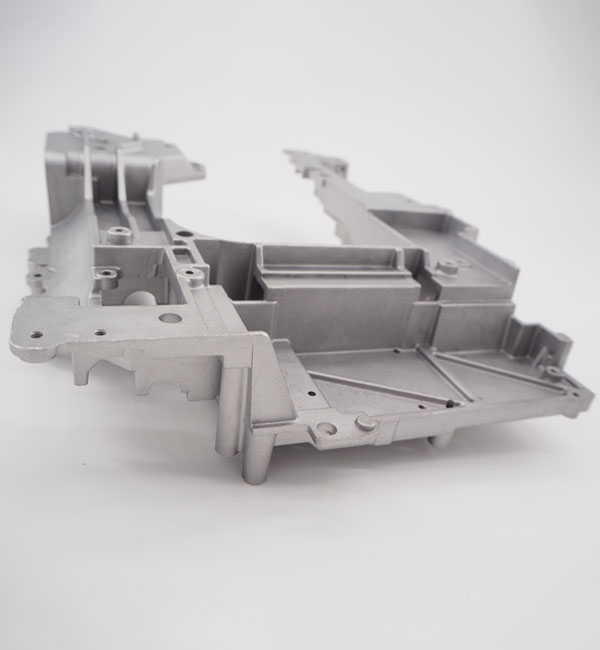

Die Casting

Die CastingDie casting is a metal casting process, which is characterized by applying high pressure to the molten metal using the cavity of the mold. Molds are usually made of higher-strength alloys, and this process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin, and lead-tin alloys and their alloys. Minghe has been China's top die casting service since 1995.

Centrifugal Casting

Centrifugal CastingCentrifugal Casting is a technique and method of injecting liquid metal into a high-speed rotating mold, so that the liquid metal is centrifugal motion to fill the mold and form a casting. Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; it affects the crystallization process of the metal, thereby improving the mechanical and physical properties of the casting.

Low Pressure Casting

Low Pressure CastingLow Pressure Casting means that the mold is generally placed above a sealed crucible, and compressed air is introduced into the crucible to cause a low pressure (0.06~0.15MPa) on the surface of the molten metal, so that the molten metal rises from the riser pipe to fill the mold and control solidified casting method. This casting method has good feeding and dense structure, easy to cast large thin-walled complex castings, no risers, and a metal recovery rate of 95%. No pollution, easy to realize automation.