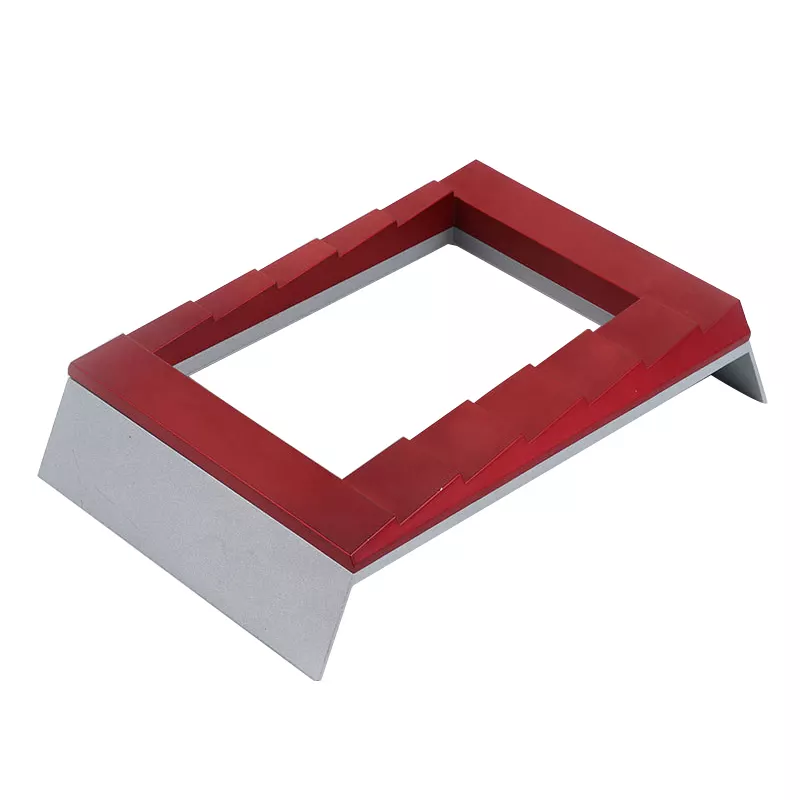

Small Speaker Enclosures

- Manufacturing Process

- Die Casting

- Parts Material

- Zinc

- Application Industry

- Smart Home Components

- Surface Treatment

- Anode Oxidation

- Metal State

- Semi-solid die casting

- Machine Used Type

- Semi-Vertical Cold Chamber Pressure Die-Casting Machine

- Hardness Of Parts

- According to customer's request

- Fillet

- According to customer's request

- Demoulding Angle

- According to customer's request

- Roughness

- According to customer's request

- Accuracy

- 0.005 mm

- 8h Casting Times

- 800-1200

Small Speaker Enclosure

ISO 14001:2015, ISO 9001:2015 and IAFT 16949:2016 certified. Custom manufacturer of Zinc Alloy Die-Cast Small Speaker Enclosure. Simple to complex and small to large parts can be fabricated. Capabilities includes mixed materials, computer aided assembly, value added assembly, mechanical assembly, metal stamping and assembly. High volume metal stamping capabilities include bending, piercing, as well as coining and tapping for other methods of modifying raw material. Secondary services such as tapping, spot welding, riveting and staking are available. Part finishing services include plating, deburring, heat treatment, cleaning, passivation and anodizing. Made in China.

Other Die Casting Parts And Machining Products

Contact Us

Tel:769-81519985

Add:102,No.41,Changde Road,Xiaojiejiao,Humen

Town,Dongguan,China

E-mail:

sales@hmminghe.com