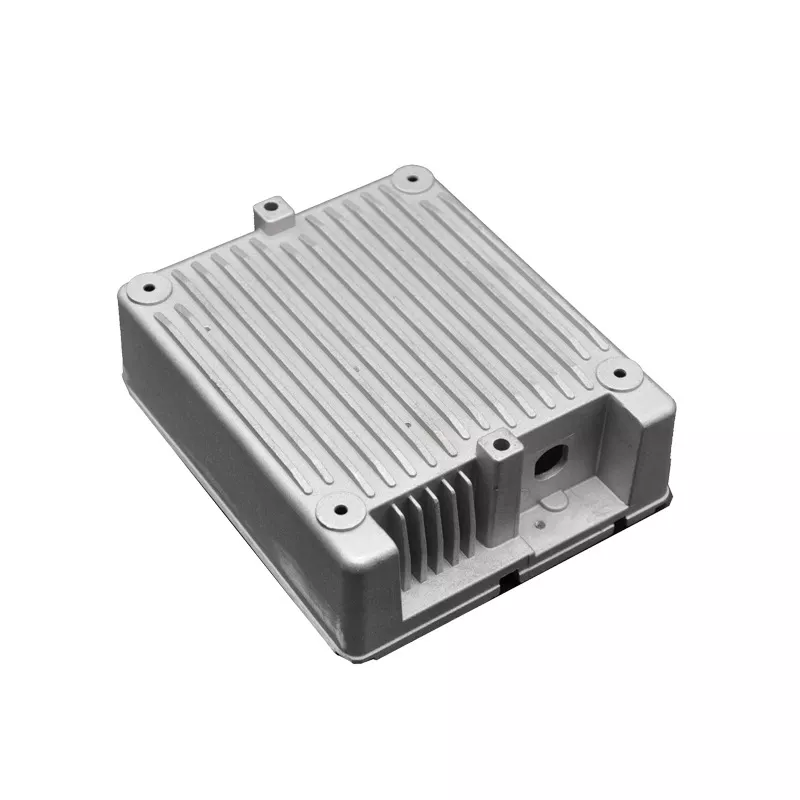

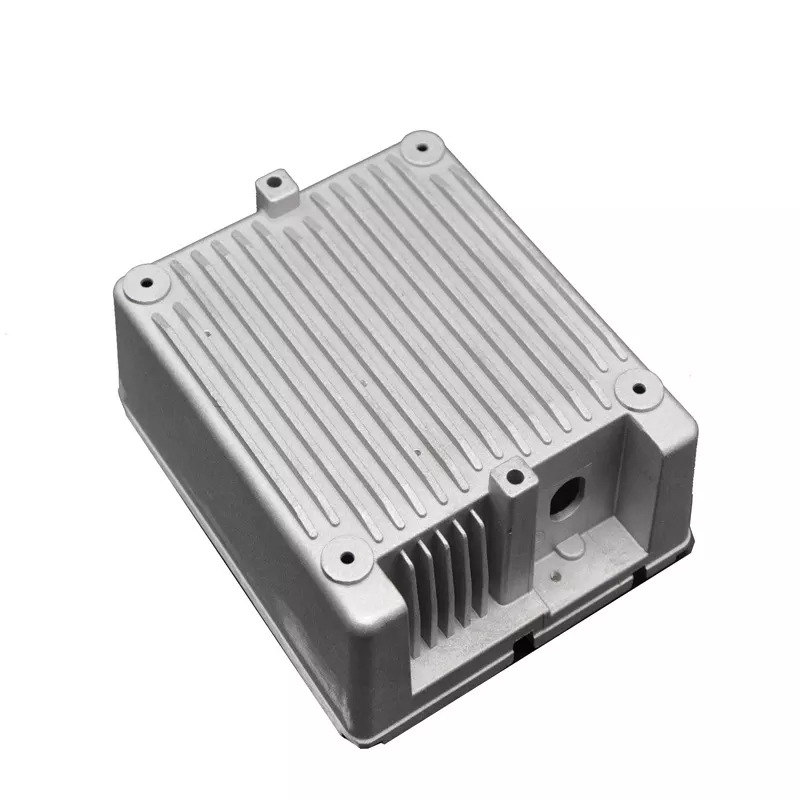

Thermal Enclosure Solutions

- Manufacturing Process

- Die Casting

- Parts Material

- Aluminium

- Application Industry

- Electronic Parts

- Surface Treatment

- Anode Oxidation

- Metal State

- All liquid die casting

- Machine Used Type

- Horizontal Cold Chamber Pressure Die-Casting Machine

- Hardness Of Parts

- According to customer's request

- Fillet

- According to customer's request

- Demoulding Angle

- According to customer's request

- Roughness

- According to customer's request

- Accuracy

- 0.005mm

- 8h Casting Times

- 800-1200

Zinc Alloy Speaker Shell Parts

Custom manufacturer of mechanical enclosure products and Custom Machining High Pressure Die-Casting Aluminum Alloy Heat Sink Box. Form-factor pluggable transceiver modules are available. Capabilities include CNC machining, EDM, die casting, progressive metal stamping, plastic injection molding, 3D printing, thin metal forming, work cell, and laser beam welding. Materials handled include plastic, zinc alloys, beryllium, brass, iron, graphite, carbon steels, HSLA steels, aluminum, 300 series stainless steel, nitonol, titanium, and platinum. Engineering services such as mechanical design and fiber optics pluggable design service are available. Markets served include aerospace, electronics, automotive, consumer products, medical, computer peripherals, military, communications and transportation.

Other Die Casting Parts And Machining Products

Contact Us

Tel:769-81519985

Add:102,No.41,Changde Road,Xiaojiejiao,Humen

Town,Dongguan,China

E-mail:

sales@hmminghe.com