Quality Assurance

The Importance of Quality Control in Die Casting Industry

The Importance of Quality Control in Die Casting Industry

In the die casting industry, quality control is a crucial aspect. An effective quality control system helps companies avoid defects, ensure compliance with standards, and improve customer satisfaction.

Our quality control team has extensive experience and expertise to ensure each die casting meets customer requirements.

Our Quality Control Methods

- ISO 9001:2015 Certification

- Incoming Inspection

- In-process Inspection

- Final Product Inspection

- Packaging Inspection

We employ a comprehensive quality control approach that includes:

ISO 9001:2015 Certification

Our factory is ISO 9001:2015 certified, demonstrating that our quality management system meets international standards.

Inspection Process

Our inspection process includes incoming, in-process, and final product inspection.

Each stage is managed by professional quality control personnel to ensure product quality.

Quality Control Process

Our quality control process includes the following steps:

Understanding Industry Background

Gain deep understanding of die casting industry characteristics and requirements as a foundation for quality control.

Product Design Review

Begin quality control at the product design stage to ensure proper design.

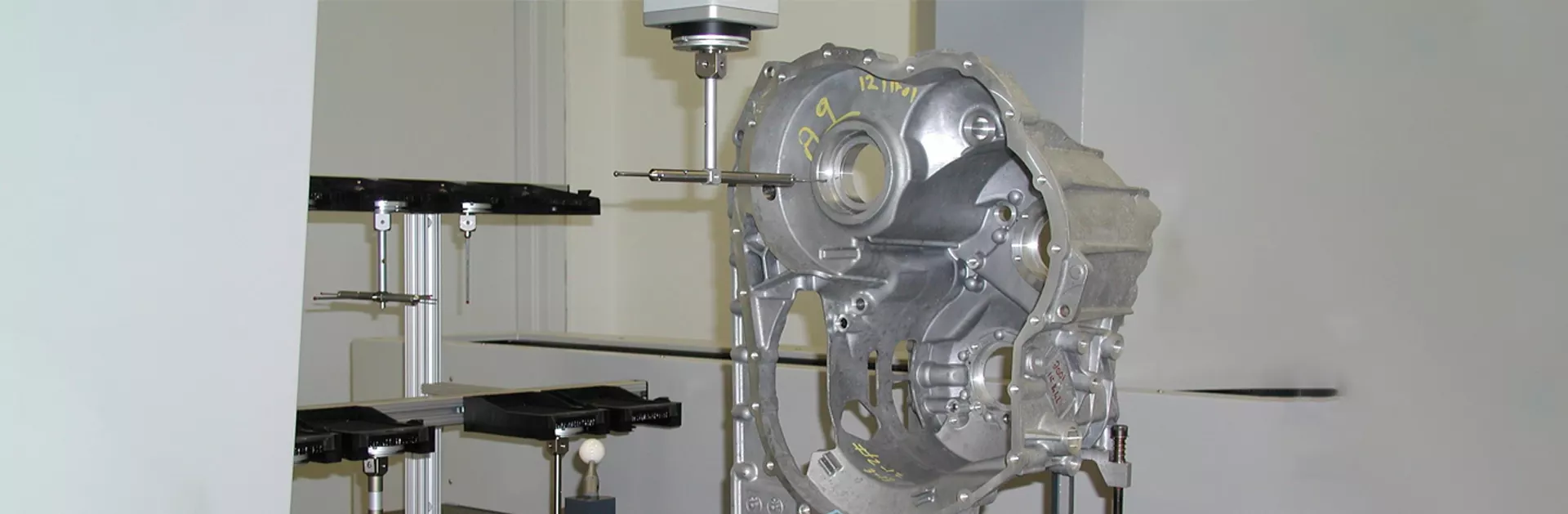

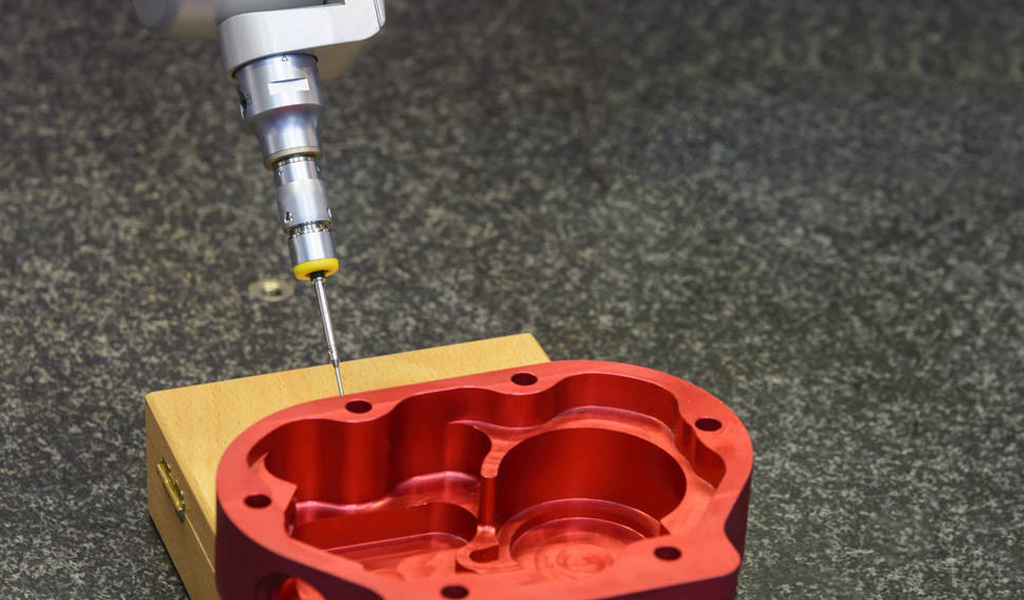

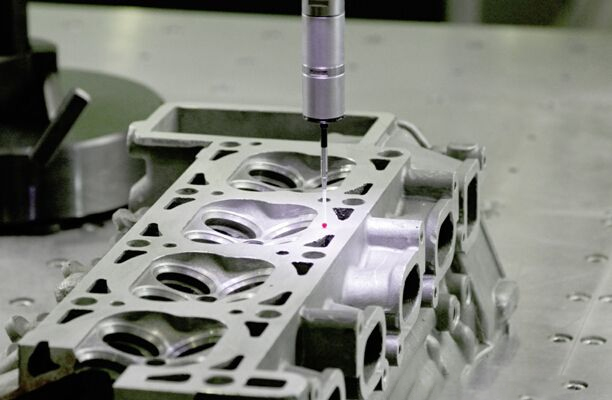

Precision Measurement

Use advanced measuring equipment to ensure precise product dimensions.

In-process Inspection

Conduct continuous quality checks during production.

Customer Communication

Maintain good communication with customers and resolve quality issues promptly.

Quality Testing Equipment

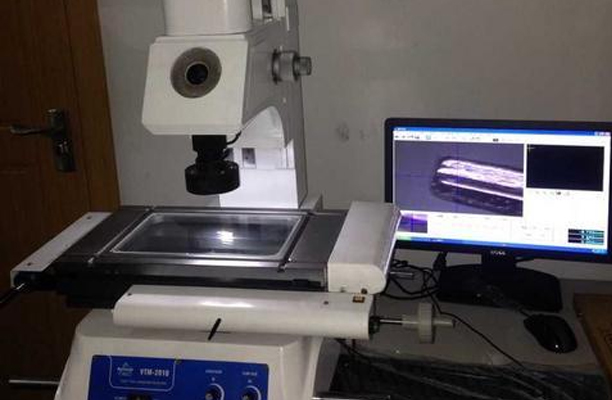

- High-precision CMM

- Complex shape measurement capability

- Accuracy up to 0.001mm

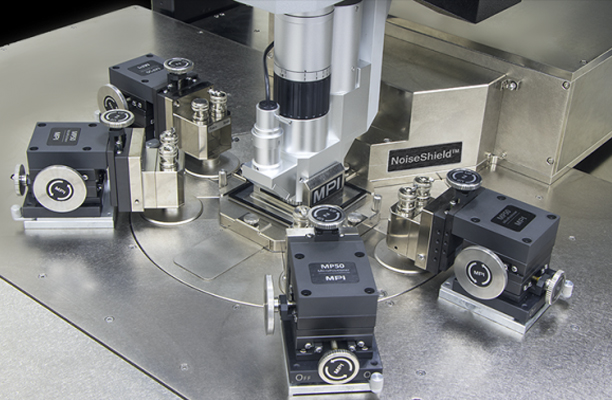

- MPI NoiseShield™ Equipment

- Surface and near-surface defect detection

- Suitable for ferromagnetic materials

- Surface roughness measurement

- Ra/Rz value measurement

- High precision

- Profile projector

- Digital micrometer

- For dimensional inspection

- Concentricity measurement equipment

- Roundness measurement

- High precision

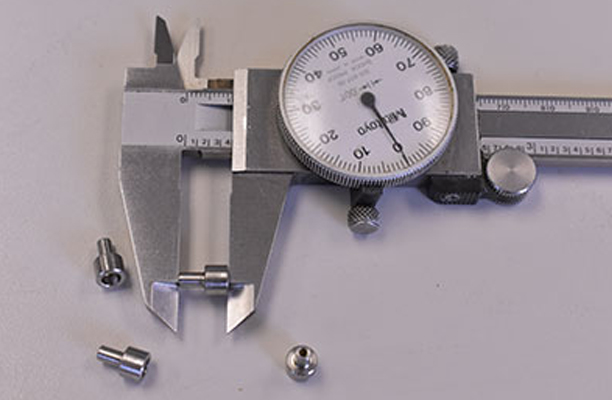

- Digital calipers

- Depth calipers

- Internal and external measurement