Production Facilities

TOOLING WORKSHOP

The tooling room is also the process equipment room, and

various tools used in the manufacturing process, such as

tools, fixtures, molds, measuring tools, inspection tools,

auxiliary tools, bench tools, station tools, etc.In

engineering and manufacturing, toolroom activity is

everything related to tool-and-die facilities in contrast

to production line activity.

|

|

Molding

|

|

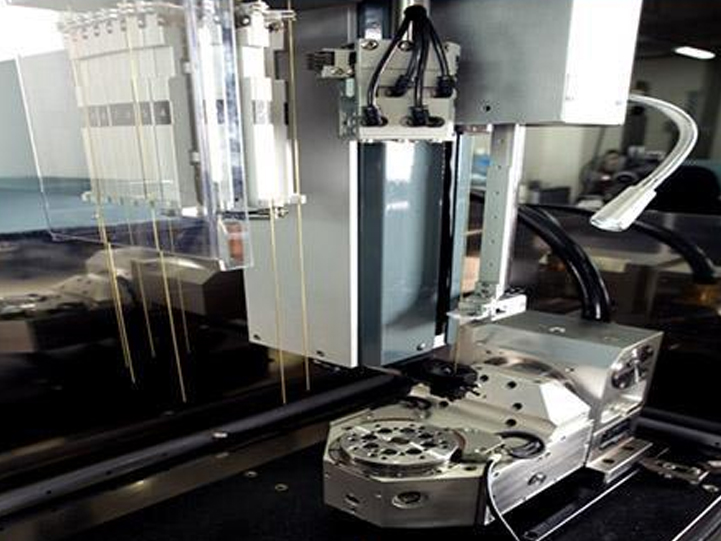

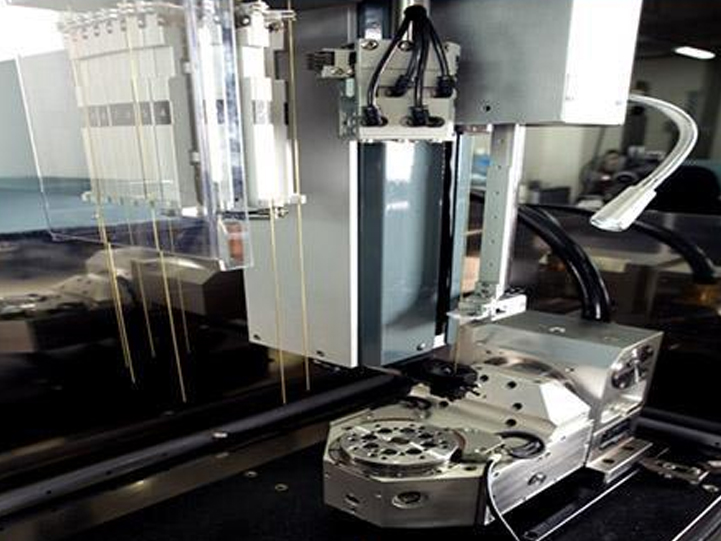

5 Axis DMU 50 DECKEL CNC Machine

|

|

Quantity: 2 Sets

|

|

|

Molding

|

|

CNC EDM Equipment

|

|

Quantity: 2 Sets

|

|

|

Molding

|

|

Universal Rocker Milling Equipment

|

|

Quantity:4 Sets

|

|

|

Molding

|

|

Universal Rocker Milling Equipment

|

|

Quantity: 1 Sets

|

|

|

Die Casting Mould

|

|

Horizontal Milling Machine

|

|

Quantity: 7 Sets

|

|

|

Die Casting Mould

|

|

Rocker Drilling Machine

|

|

Quantity: 3 Sets

|

|

|

Die Casting Mould

|

|

EDM Line Cutter Equipment

|

|

Quantity: 1 Sets

|

|

|

Die Casting Mould

|

|

EDM High Speed Piercing Equipment

|

|

Quantity: 1 Sets

|

DIE CASTING WORKSHOP

| TONNAGE |

30T |

280T |

400T |

500T |

800T |

1250T |

1650T |

2000T |

2700T |

3000T |

| SET |

15 |

13 |

3 |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

| EST CAPACITY/ MONTH |

60K |

46K |

43K |

43K |

39K |

31K |

26K |

23K |

21K |

19K |

|

TOTAL QTY: 40 SETS TOTAL CAPACITY/MONTH:351K

|

|

200 T Hot Chamber Die Casting Machine

|

|

Cold Chamber Die Casting Machine Workshop

|

|

Cold Chamber Die Casting Machine Workshop

|

|

3000T LIBI DIE CASTING MACHINE

|

|

SANJI Overhaul 550t Die Casting Machine

|

|

SANJI Overhaul 550t Die Casting Machine

|

CNC MACHINING WORKSHOP

| NAME |

3 AXIS CNC MACHINE |

4 AXIS CNC MACHINE |

5 AXIS CNC MACHINE |

PRECISION LATHE |

CNC ENGRAVING |

5 AXIS TURN-MILL MACHINE |

| SET |

30 |

18 |

2 |

15 |

3 |

1 |

| EST CAPACITY/ MONTH |

6K |

5K |

2K |

15K |

2K |

1K |

|

TOTAL QTY: 69 SETS TOTAL CAPACITY/MONTH:31K

|

|

5 Axis CNC ENGRAVING MACHINE

|

|

YIMEI Single Column Cnc Turn-Mill Center

|

|

Shenyang Cnc Turning Machine

|

OTHER PRODUCTION FACILITIES

Minghe Casting has world class infrastructure with Highly

mechanized and versatile foundry, state-of-the-art Machine

shop with large scale process capability and sophisticated

testing lab to produce high quality Casting Components.

|

|

Wax Department

|

-

High tech wax injection presses

-

Conditioning tank with calibrated digital

temp. Controller

-

Specially designed fixtures for fast

production

|

|

|

Coating Department

|

-

Separate primary coat area

-

Separate drying room for controlling

humidity & temperature by air

conditioning & de-humidifier

|

|

|

Melting Department

|

-

Medium frequency induction furnace of 250

kw/250 kg

-

Chemical and physical lab is situated very

near to melting area

|

|

|

Heat-treatment Department

|

-

Heat-treatment shop is equipped with gas

fired furnace

-

Heat-treatment shop is equipped with gas

fired furnace

-

Fully computerized control for achieving

desired temp in desired manner

|

|

|

Sand Casting Department

|

-

Coastal Sand Mixer Continuous Sand Mixer

-

Centrally air-conditioned well equipped Sand

Casting

-

Larger continuous sand mixer with dual

hopper, automated controls, and mechanical

reclaim.

|

|

|

CLEAN ROOM

|

-

1 Wheelabrator cubic foot Stainless steel

tumble blast Machine

-

1 Wheelabrator 3 cubic foot steel tumble

blast machine

-

1 Pangborn 5 station Stainless steel rotary

table blast

|