In the stage of die-casting new product development and new mold trial, there will be more or less problems that lead to failure of the trial. And there are many factors that affect the failure of the model test. What are the relevant factors?

First of all, review and analysis of the casting structure and mold gating system design in the development stage. Secondly, the process parameters of die-casting production such as molten metal temperature, die-casting pressure, speed and fast switching point are reasonable. And so on, some factors are the key to directly affecting the internal and external quality of die castings.

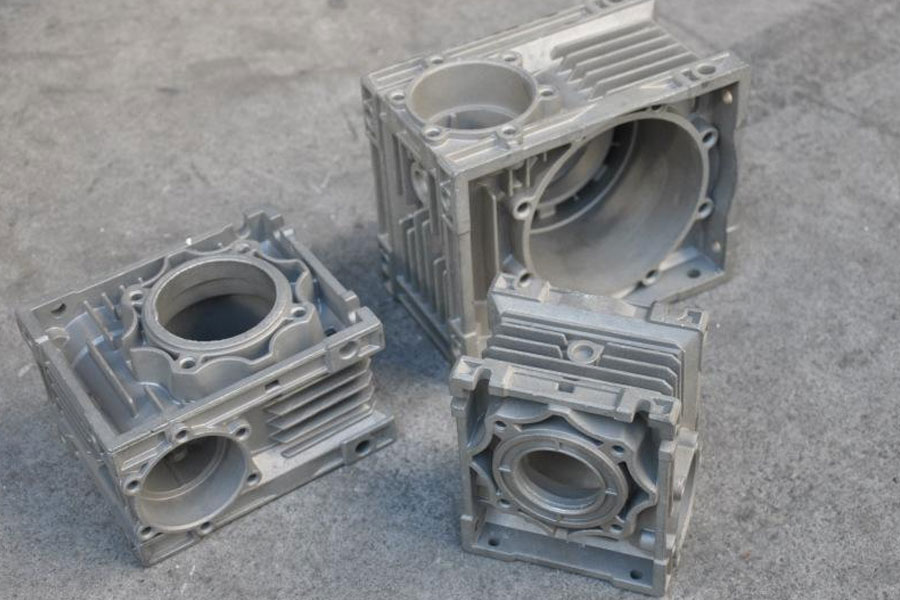

But in most cases, mold design and production are closely related. Factors that affect the mold, including the number of cavities, the design of the gate system, the type of gate (position, area, direction), etc., for castings with large wall thickness differences, local high-pressure spot cooling and core cooling are also used. To achieve the purpose of balancing the mold temperature. Only with a good mold design can a wider range of process parameters be obtained, which is more conducive to the internal and external quality of the casting. For specific review and analysis, we have to use some auxiliary software. For example: mold flow analysis software, process parameter analysis software PQ 2 diagram and so on.

Theoretical Data Analysis

1) Analyze the initial design of the gate location, area and direction, the location of the slag bag exhaust, etc. through the mold flow software. Understand the entrainment, temperature distribution, flow path and velocity of the molten metal flowing in the cavity, as well as the slag collection and exhaust of the slag bag, and find out the problems to provide a basis for the next review and modification, so as to get Better gating system.

2) Using the PQ 2 diagram to insert the mold, equipment and other parameters analysis, we can initially set the process parameters and the rationality of the press tonnage selection, find out the problems in the process parameter settings and correct them in time; and we can also get the theory The above process parameters have guiding significance for the adjustment of the process parameters of the die casting machine.

Die Casting Mold Trial And Process Parameter Optimization

The main purpose of mold trial is to find out the optimized process parameters and mold modification plan. It is required that even if the materials, machine settings or environmental factors have changed, it can still ensure that the mold can stably and uninterruptedly produce qualified products in batches. Improve the "adaptability" of the mold to the limit, not just to get a few good test mold samples.

Preparatory work before mold test. According to the design drawings of the mold, perform a detailed inspection of the relevant dimensions (especially the size of the sprue bushing interface); figure out the action sequence of each movable part of the mold (core pulling and slider); confirm what is to be adopted The die casting machine model, injection position, tubing interface, pressure chamber diameter and interface size are consistent with the actual requirements of the mold. Special attention must be paid to the die-casting machine used in the trial mold must match the model of the die-casting machine used in the mass production of the mold, otherwise the mold may be unusable.

According to the theoretical process parameters obtained from the PQ2 chart, trial production is conducted to find the difference between actual and theoretical parameters. And continue to adjust and modify, until a well-formed casting with good internal quality is obtained. Among them, the performance of the press may be unstable, which makes it difficult for us to judge the problem. At this time, the "injection monitor" can be used to monitor the speed, pressure, displacement and other parameters in the injection process, and judge by the fluctuation of the curve. Help us accurately find the problem, effectively guide the correction of process parameters and understand the performance of the equipment. In the end, a set of optimal process parameters suitable for this equipment will be obtained.

The molds produced by the mold factory are often due to poor design considerations or improper processing in the production process. There are often some problems, such as over-tolerance, unsmooth local transitions, improper structure, and unreasonable cooling water layout. Large temperature difference, etc., resulting in unqualified castings or failure of mold trial production. Due to the difference between actual results and theory, mold trial is the simplest, direct and effective way to find out mold problems. You can also know the temperature distribution of the mold and whether the cooling water location is reasonable through the thermal imaging diagram, which is very helpful to extend the life of the mold. It also has guiding significance for spray adjustment.

In the trial mold process, the trial mold parts produced after the process parameters are stabilized require on-site review by product engineers, process technicians and quality engineers according to customer requirements. The main review contents are:

Die-casting mold trial is not only a process of theoretical and practical derivation and verification, but also a process of continuous error correction and improvement. Moreover, contemporary die-casting has more high-tech auxiliary software and equipment to help us test the mold more scientifically. Make a systematic analysis of the casting structure, mold structure, die-casting process and the performance of die-casting equipment to find out the differences and problems. After the problem is solved, the mold structure and process parameters are optimized. Make our molds more suitable for stable production and quality maintenance. This fully embodies the significance of die-casting mold trial.