Melt leakage caused by process factors

Improper operation technology is one of the main reasons for melt leakage during mold production. In order to compensate for the thermal expansion of the parts of the hot runner system, there is often a certain cold gap between the parts when designing and assembling the mold. Only under the specified operating temperature, the thermal expansion of the parts can completely eliminate the cold gap and achieve sealing and leakage prevention. Melt leakage caused by improper operation mainly occurs in the following situations:

On the other hand, when the temperature of the gating system is reduced to the operating temperature, melt leakage will also occur due to the poor adaptability of the thermal nozzle with rigid edges to thermal expansion.

In summary, operating according to the correct steps and process conditions is a prerequisite to avoid melt leakage. The general hot runner mold can be operated according to the following steps:

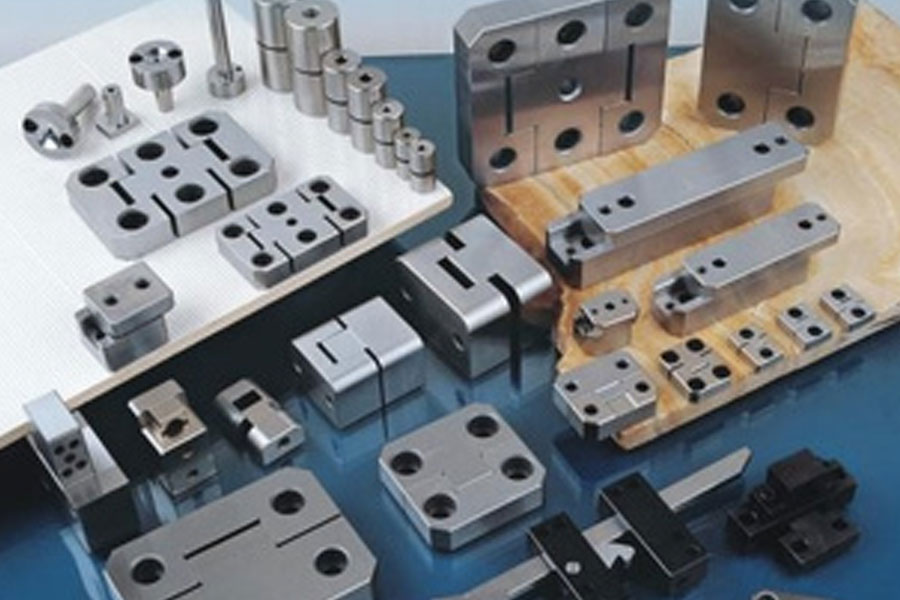

Sealing design of hot runner system

Thermal expansion compensation of hot runner system

The mold assembled at room temperature will cause the relative position of the parts to change during the thermal expansion of the parts of the hot runner system. In order to compensate for the thermal expansion of the parts, it is necessary to leave a suitable expansion gap, such as the cold gap A and C shown. It is fixed on the fixed template 1 by the center positioning pin 7 and stretches around after being heated. The transverse thermal expansion of the hot runner plate will reduce the gap A between the hot runner plate and the anti-rotation pin 2. If the value A is smaller than the transverse thermal expansion of the hot runner plate in the design, the anti-rotation pin will prevent the transverse extension of the hot runner plate after heating.

It causes the warpage and deformation of the hot runner plate, which makes the seal between the hot runner plate and the nozzle ineffective and causes melt leakage. The axial thermal expansion of the support ring 6, the hot runner plate 5, and the gate nozzle 4 will eliminate the cold gap C. If the cold gap is too large and the axial thermal expansion is insufficient, the melt pressure during injection will cause the gate nozzle 4 and the hot runner The plate 5 is separated and the melt leaks. If the cold gap is too small and the thermal expansion pressure of the system is too large, the system parts will be bent, or the compressive stress will exceed the yield stress of the fixed template, which will cause the support ring to crush the fixed template, thereby limiting the lateral thermal expansion of the hot runner plate and causing the gate Melt leakage occurred between the nozzle and the hot runner plate.

Therefore, when designing the mold, correctly calculating the thermal expansion of the system and leaving a reasonable thermal expansion gap are the prerequisites to prevent melt leakage. The linear thermal expansion of the system can be calculated by the following formula: L=TL (1) The thermal stress caused by the resistance of the thermal expansion of the system is: =EL-CL (2) The pressure of the fixed mold fixed plate is checked by the following formula p(3) where: L Is the linear thermal expansion of the hot runner system, mm; is the linear thermal expansion coefficient of the system parts material; T is the temperature difference between the hot runner system parts and the mold; L is the length of the runner system parts in the expansion direction at room temperature, mm; is the system thermal expansion The thermal stress caused by resistance, MPa; C is the amount of reserved gap, mm; E is the elastic modulus of the system parts, MPa; p is the allowable compressive stress of the fixed mold plate material.

The sealing form of the hot runner system

The plane seal between the hot runner plate and the nozzle is a common sealing form in foreign hot runner systems. After the system is thermally expanded in the axial direction, the support ring is pressed on the fixed mold plate, and a certain thermal pressure is generated at the joint plane of the hot runner plate and the nozzle to offset the melt pressure to seal and prevent leakage. This type of structure cannot guarantee cold sealing, and there is no overheating protection measure. Only under the set temperature conditions can the hot runner plate and the nozzle be sealed. When designing, it is necessary to accurately calculate the thermal expansion and leave a suitable cold gap C.

b. O-shaped sealing ring is used on the joint plane of nozzle and hot runner plate. O-shaped sealing ring is made of stainless steel pipe. When assembling, there is a preload of 2030 steel pipe diameter to prevent melt leakage. This structure is very suitable for low-rigidity hot runner plates and molds.

The elastic connection is adopted, and the spring provides pre-tension to realize the sealing under the cooling state. When overheating, the spring absorbs thermal expansion to prevent system damage and leakage. It is an ideal sealing form.

The gate nozzle is fixed on the hot runner plate by threads, and the nozzle and the sliding pressure ring move with the hot runner plate when the system thermally expands. Since the movement of the nozzle will cause the misalignment of the nozzle runner axis and the gate axis on the fixed template, the lateral thermal expansion should be considered when designing the nozzle position. This type of sealing is suitable for occasions with few injection points and small nozzle spacing.

Hot runner plate assembly process

The assembly accuracy and installation sequence of the hot runner system are directly related to whether the melt leaks. If the nozzle height is inconsistent, the gap between the shortest nozzle and the hot runner plate will cause melt leakage, and the deformation of the hot runner plate caused by the inconsistent height of the support pad and the nozzle height will also cause melt leakage.

The following takes a 1-mold 4-cavity plastic box hot runner mold as an example to illustrate the assembly process of the hot runner plate: