Magnesium alloy injection molding technology has become a research hotspot in the industry due to its many advantages. There are three kinds of injection molding technologies that have appeared recently: hot runner method, casting forging method and powder release agent.

The basic principle of injection molding is to melt the low melting point alloy, and then fill it into a metal mold at high speed and high pressure. The raw materials of the size of rice grains are fed from the feeding port, and then they are fed into the cylinder heated to the set temperature and transported to the front end. At this time, the shear force is increased by rotating the wire, and the alloy melt is made into a semi-molten state, and then injected into the metal mold at a high speed. The temperature of the alloy melt is maintained at 560 to 630°C, and the solid phase ratio is controlled. What Japan Steel introduces is the technology patent of American Thixomat Company, and manufactures and sells forming machines.

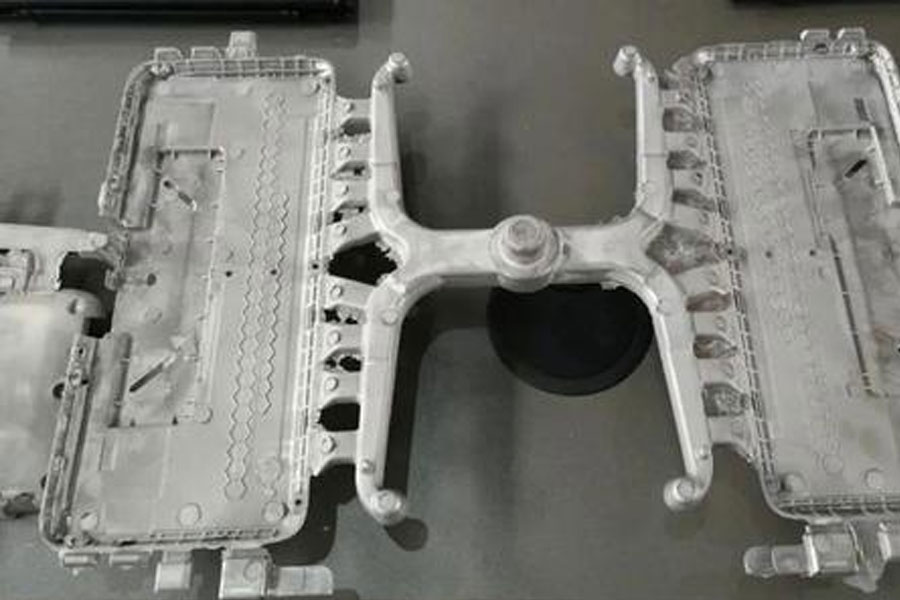

Compared with the die casting china method, the magnesium alloy injection molding method has a higher casting pressure, so the crystal grains near the surface are refined, so that high corrosion resistance and mechanical strength can be obtained. The reproducibility of the metal mold is also good. Because the temperature of the alloy melt is 50 to 70°C lower than that of the die-casting method, the size change of the molded product with the heat shrinkage can be controlled, thereby increasing the service life of the metal film. In addition, no melting furnace and SF6 flame-proof gas are used, explosion and dust will not occur, and it meets safety and environmental protection requirements.

The latest injection molding technology: