Under the control of ISO9001 and TS 16949,All

processes are carried out through hundreds of

advanced die casting machines, 5-axis machines,

and other facilities, ranging from blasters to

Ultra Sonic washing machines.Minghe not only has

advanced equipment but also have professional team

of experienced engineers,operators and inspectors

to make the customer's design come true.

Contract manufacturer of die castings.

Capabilities include cold chamber aluminum die

casting parts from 0.15 lbs. to 6 lbs., quick

change set up, and machining. Value-added services

include polishing, vibrating, deburring, shot

blasting, painting, plating, coating, assembly,

and tooling. Materials worked with include alloys

such as 360, 380, 383, and 413.

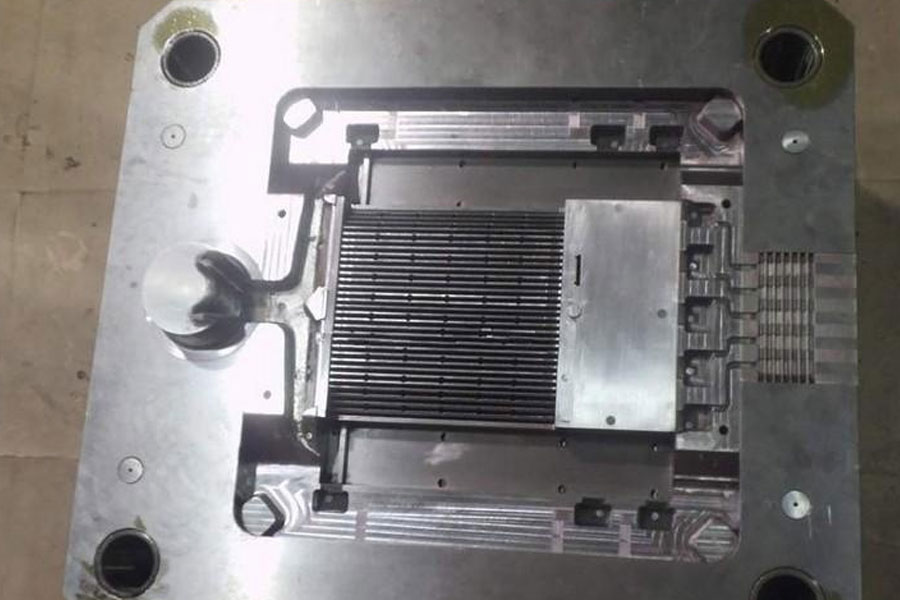

Zinc die casting design assistance/concurrent

engineering services. Custom manufacturer of

precision zinc die castings. Miniature castings,

high pressure die castings, multi-slide mold

castings, conventional mold castings, unit die and

independent die castings and cavity sealed

castings can be manufactured. Castings can be

manufactured in lengths and widths up to 24 in. in

+/-0.0005 in. tolerance.

ISO 9001: 2015 certified manufacturer of die cast

magnesium, Capabilities include high-pressure

magnesium die casting up to 200 ton hot chamber

& 3000 ton cold chamber, tooling design,

polishing, molding, machining, powder & liquid

painting, full QA with CMM capabilities, assembly,

packaging & delivery.

ITAF16949 certified. Additional Casting Service

Include investment casting,sand casting,Gravity

Casting, Lost Foam Casting,Centrifugal

Casting,Vacuum Casting,Permanent Mold

Casting,.Capabilities include EDI, engineering

assistance, solid modeling and secondary

processing.

Casting Industries Parts Case Studies for: Cars,

Bikes, Aircraft, Musical instruments, Watercraft,

Optical devices, Sensors, Models, Electronic

devices, Enclosures, Clocks, Machinery, Engines,

Furniture, Jewelry, Jigs, Telecom, Lighting,

Medical devices, Photographic devices, Robots,

Sculptures, Sound equipment, Sporting equipment,

Tooling, Toys and more.