The machining technology of CNC lathes is similar to that of ordinary lathes, but because CNC lathes are one-time clamping and continuous automatic machining to complete all turning processes, the following aspects should be paid attention to.

1. Reasonable Choice Of Cutting Amount

For high-efficiency metal cutting machining, the material to be processed, cutting tools, and cutting conditions are the three major elements. These determine the machining time, tool life and machining quality. The economical and effective machining method must be a reasonable choice of cutting conditions.

The three elements of cutting conditions: cutting speed, feed rate and depth of cut directly cause tool damage. With the increase in cutting speed, the temperature of the tool tip will rise, which will cause mechanical, chemical, and thermal wear. Cutting speed increased by 20%, tool life will be reduced by 1/2.

The relationship between the feed condition and the wear on the back of the tool occurs in a very small range. However, the feed rate is large, the cutting temperature rises, and the back wear is large. It has less influence on the tool than cutting speed. Although the influence of cutting depth on the tool is not as large as the cutting speed and feed rate, when cutting at a small depth of cut, the material to be cut will produce a layer, which will also affect the life of the tool.

The user should select the cutting speed to be used according to the processed material, hardness, cutting state, material type, feed rate, depth of cut, etc.

The selection of suitable machining conditions is selected on the basis of these factors. Regular, stable wear and longevity are the ideal conditions.

However, in actual operations, the choice of tool life is related to tool wear, dimensional changes to be processed, surface quality, cutting noise, and machining heat. When determining the machining conditions, it is necessary to conduct research according to the actual situation. For difficult-to-process materials such as stainless steel and heat-resistant alloys, coolants or blades with good rigidity can be used.

2. Reasonable Choice Of Tools

3. Reasonable Selection Of Fixtures

4. Determine The Machining Route

The machining route is the movement track and direction of the tool relative to the part during the machining of the index-controlled lathe.

5. The Connection Between Machining Route And Machining Allowance

At present, under the condition that the CNC lathe has not yet reached the popular use, the excess margin on the blank, especially the margin containing the forging and casting hard skin layer, should be arranged on the ordinary lathe for machining. When machining manufacturers must use CNC lathes, they need to pay attention to the flexible arrangement of the program.

6. Main Points Of Fixture Installation

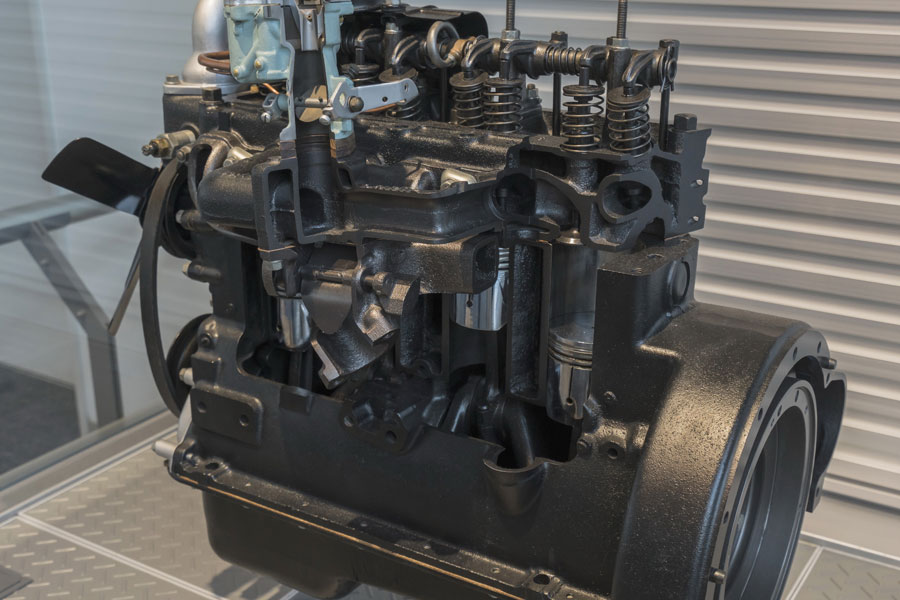

At present, the connection between the hydraulic chuck and the hydraulic clamping cylinder is realized by a tie rod, as shown in Figure 1. The main points of hydraulic chuck clamping are as follows: first use a moving hand to remove the nut on the hydraulic cylinder, remove the pull tube, and pull it out from the rear of the spindle, and then use the moving hand to remove the chuck fixing screw to remove the chuck.

The wiper edge on the tool refers to a small segment of the blade parallel to the tip of the tool that is ground in the direction of the secondary deflection angle behind the blade of the tool. It is mainly used for a secondary cutting after the cutting of the blade. Improving the surface roughness of the workpiece is mostly applied to the knife for finishing.

The machining technology of CNC lathes is similar to that of ordinary lathes, but because CNC lathes are one-time clamping and continuous automatic machining to complete all turning processes, the following aspects should be paid attention to.