Stamping processing has many unique advantages in terms of technology and economy; the main advantages are high production efficiency, convenient operation, and easy realization of mechanization and automation.

Die casting is a method of casting die forging. The die-casting die forging process is a dedicated process performed on a die-casting die forging machine. It is a method of pouring the fusion gold liquid into the press chamber to fill the cavity of the steel mold at high speed. And make the alloy liquid solidify under pressure to form a casting method;

The basic process of die-casting is that the molten metal is first filled into the cavity of the mold at low or high speed. The mold has a movable cavity surface. It is pressurized forged with the cooling process of the molten metal, which eliminates the shrinkage of the blank. Shrinkage defects also make the internal structure of the blank reach broken grains in the forged state, and the comprehensive mechanical properties of the blank have been significantly improved. In addition, the rough produced by this process has a surface finish of 7 (Ra1.6), which is like the surface produced by cold extrusion or machining, with metallic luster. Therefore, we call the die-casting die forging process "Ultimate Forming Process"

The Difference Between Die Casting Parts And Stamping

Although they are all metal processing techniques, there are big differences between them:

Metal stamping is a process that uses punches and molds to deform or break stainless steel, iron, aluminum, copper and other plates and other materials to achieve a certain shape and size.

Die-casting is a kind of pressure-casting parts. It uses a pressure-casting mechanical die-casting machine equipped with a casting mold to pour the heated liquid copper, zinc, aluminum or aluminum alloy into the inlet of the die-casting machine, and pass it through the die-casting machine. Die casting is to cast copper, zinc, aluminum parts or aluminum alloy parts of the shape and size restricted by the mold. Such parts are usually called die-casting parts.

Die casting and stamping are both the processing and forming methods of parts, but die casting uses pressure to fill the mold with liquid metal to obtain the same parts as the mold; stamping uses the function of the mold to remove some parts of the solid metal to obtain the required parts .

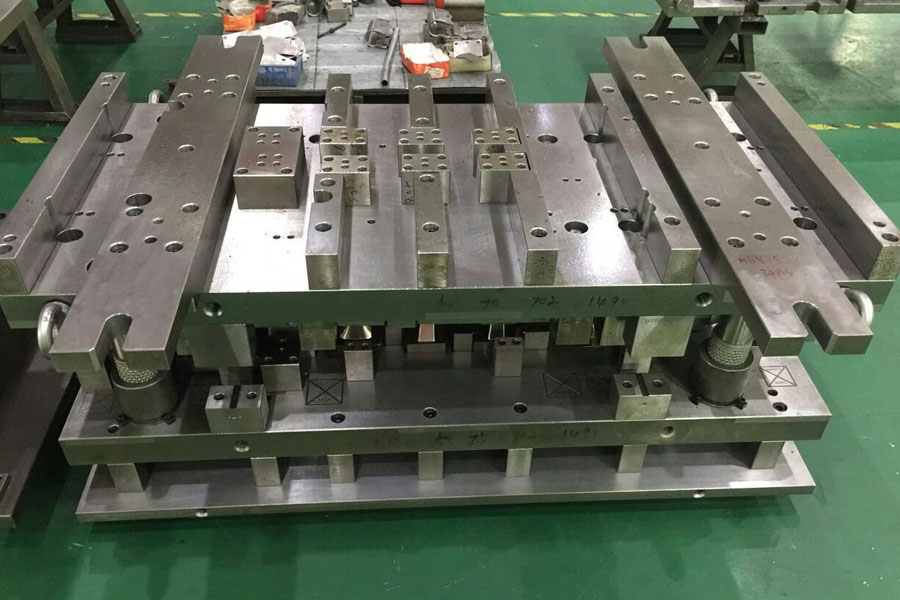

The Difference Between Die Casting Mold And Stamping Mold

Stamping is divided into cold stamping and hot stamping. Compared with cold stamping, the hot stamping process can effectively take into account the issues of lightweight and collision safety, and high-strength stamping parts springback and die wear. Hot stamping is realized through its forming die. Whether the design of the die is reasonable or not will directly affect the efficiency of hot stamping.

The design and manufacturing methods of hot stamping dies are mainly divided into four types: drilling type, layered type, shower type and casting type.

1. Drilling type

The drilling type realizes the arrangement of the insert cooling system by arranging the pipes as follows to the maximum extent under the convex-concave model surface. The advantages are easy processing, easy replacement of molds, and good versatility;

The disadvantages are: inability to follow the shape processing, and poor mold cooling uniformity.

2. Hierarchical

The layered type is designed and processed through the layered design and processing of the mold surface and other parts of the mold with the cooling pipe as the interface. The advantages are good conformability, large heat exchange area and simple sealing;

The disadvantage is that high-precision processing equipment is required, the cooling pipeline is complicated, and the heat transfer performance is poor.

3. Shower type

In the shower type, a series of small holes are opened on the mold surface, and nozzles are arranged in the holes. After the mold is closed, the nozzle is used to spray high-pressure coolant onto the hot steel plate in mist to achieve quenching and cooling. The advantage is that the cooling effect is good, the machining material phase change is sufficient, and the mechanical properties of the parts are excellent;

The disadvantage is that it is difficult to process, and the residual water droplets on the mold cause serious damage to the mold surface and reduce the life of the mold.

4. Casting type

The melt-casting type is entirely pre-embedded into the sand mold through a fixed cooling pipe, and the mold blank is obtained by casting, and an integrated mold is obtained after machining. The advantages are the flexible arrangement of cooling pipes, good conformability, simple and reliable pipe sealing, and easy processing;

The disadvantage is that the mold strength is poor, the melting and casting process is complex, the metallurgical combination between the pipe and the substrate is required, the position accuracy is high, and it is difficult to achieve partial mold repair.

Among the four hot stamping die design and manufacturing methods, the drilling type and the layered type are the most widely used.