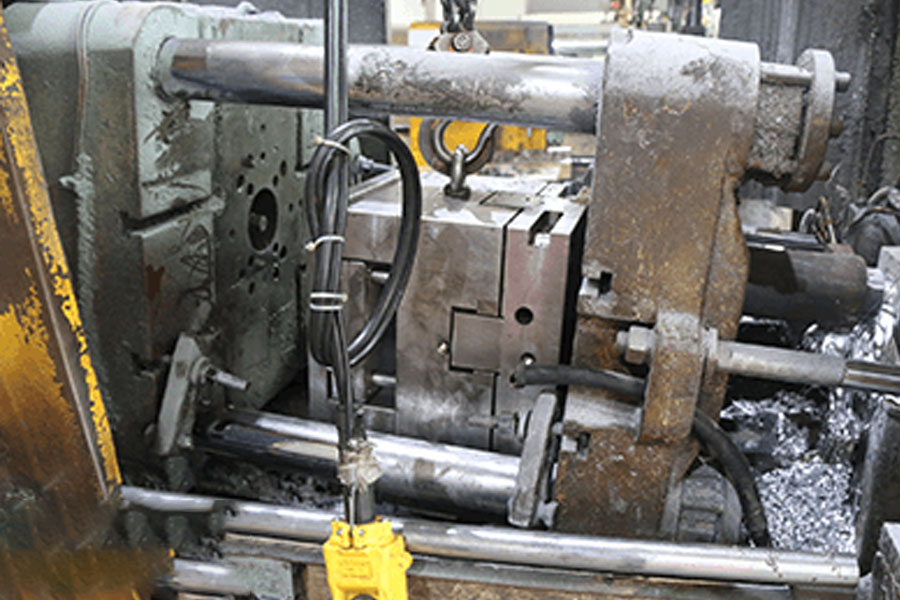

The working conditions of aluminum alloy die-casting molds are compatible with high temperature and high pressure. At the same time, the aluminum alloy die-casting mold in working mode needs to withstand the repeated impact of liquid metal. In actual production, due to the high cost of aluminum alloy die-casting molds, long production cycle, and premature failure, the service life will be greatly shortened. -Once the problem of cracking and failure of aluminum alloy die-casting molds is not effectively solved, it will directly affect the economic benefits of the production enterprise. For this reason, more and more aluminum alloy die-casting manufacturers have increased their crack failure analysis. The following content takes H13 steel hot work die steel as an example, and combines the actual production process to analyze the causes of cracking and failure of aluminum alloy die-casting molds from the aspects of aluminum alloy mold material, microstructure and electric discharge machining. Corresponding measures have been taken.

1. Cause Analysis Of Aluminum Alloy Die-Casting Mould Cracking Failure

Chemical Composition

From the point of view of chemical composition, H13 steel type hot work die steel mainly covers the concentrated elements of C, SijMn, Mo, Cr, and V. From the point of view of chemical characteristics, H13 steel type hot work die steel belongs to low Si and high Mo hot work die steel in terms of material. In the production process, manufacturers will appropriately reduce the Si content or increase the Mo content in the steel according to actual needs. By reducing the Si content, the bias can be effectively reduced

The occurrence of precipitation phenomenon, and further refine the austenite grains, improve the strength and toughness of steel. Increasing the content of Mo can improve the hardenability, tempering resistance and heat resistance of steel. And effectively prevent the precipitation of grain boundary carbides in the steel, as well as the transformation of bainite. Practice has shown that low Si and high Mo steel will reduce the probability of undercooling during the solidification process, thereby effectively preventing the occurrence of dendrites, cellular columnar crystals and dendrite segregation. The combination of Mo and V elements can form alloy carbides, such as VC, MoC and Mo2C. Alloy carbides will precipitate in a finely dispersed state under suitable high temperature conditions, which will greatly improve the thermosetting properties of high temperature materials. Although in terms of chemical composition, H13 steel type hot work die steel has strong crack resistance, in actual operation, we found that H13 steel type hot work die steel has early cracking failure. In order to better analyze the causes of crack failure, it is necessary to effectively combine the microstructure of H13 steel hot work die steel for further analysis.

Microstructure

In order to comprehensively study the microstructure of aluminum alloy die-casting molds, this part uses mold materials that have not been put into use after vacuum quenching and tempering and used mold materials as the research objects to analyze the microstructure of aluminum alloy die-casting molds, and then find out Causes of cracking failure.

Mold Materials That Have Not Been Put Into Use After Vacuum Quenching And Tempering

Through practice, it is found that there are uneven tissues distributed on the substrate of the research object after heat treatment. By observing the research object under a low-power microscope, we found that a large number of precipitated granular carbides are distributed on the matrix and segregated. In other words, compared with the carbides of normal tissues, this part of the carbides Larger in volume. Due to the excessive precipitation of carbides and alloy carbides, the mold material loses a large amount of surrounding carbon and alloying elements. Under normal circumstances, the segregated carbides of the mold will not easily dissolve when the mold is heated by quenching. However, due to its lack of carbon and alloying elements, it is easy to change to martensite under high temperature heating, thereby reducing Tempering the quality star, and greatly reduces the strength and toughness of the steel, making it easy to fracture just now. By using a low power microscope to observe the annealed steel before vacuum quenching, we found that the steel matrix also has segregation. The appearance of this phenomenon means the lack of uniformity of steel raw materials. And once the segregation phenomenon is not effectively dealt with, it will increase the risk of mold cracking and failure, and affect the final service life of the mold.

Mold Material After Use

In actual production, general H13 steel hot work die steel molds will appear to different degrees of cracking on the surface of the mold after about 30,000 times of use, such as: intergranular fractures and the intersection of multiple cracks After peeling, pits and the like are formed. The reason for this phenomenon is mostly due to metallurgical defects in the raw materials.

EDM

EDM is one of the commonly used processing methods in aluminum alloy die-casting molds. Compared with other processing methods, this processing method presents the advantages of high processing accuracy, high level of automation and ease of processing irregular-shaped parts in the specific application process. Nevertheless, the sparks released during processing have the characteristics of high temperature and high pressure, and the temperature of the working fluid will be

The sharp decline has caused the steel surface to be divided into thermal remelting zone and heat-affected zone. The so-called thermoremelting zone means that the surface metal is melted by the high temperature released during discharge. Because the melt is not completely thrown out, and the retained melt solidifies as the working fluid cools. The thermal remelting zone is mostly distributed on the uppermost layer of the steel surface. Compared with the heat-affected layer in the thermal remelting zone, the metal material is affected

After being burned at high temperature, no melting phenomenon occurred, but the metallographic structure of the material changed accordingly. Through a lot of practice, we found that the hot mold process will also increase the risk of mold cracking and failure in the hot remelting zone and the heat affected zone. After the aluminum alloy die-casting mold after EDM passes through the gas furnace, although the metallographic structure of the mold does not change accordingly, it is thermally remelted.

However, slight cracks will appear in the zone, and when the cracks extend to the heat-affected zone, the micro-crack range will increase again, which in turn increases the degree of mold cracking failure.

2.Preventive Measures Against Cracking Failure Of Aluminum Alloy Die-Casting Mold

3. Conclusion

In short, with the rapid development of my country's social economy, aluminum alloy die-casting mold manufacturers have rapidly expanded in terms of number and production scale. However, due to the large investment in the production cost of aluminum alloy die-casting molds, once the production quality cannot be effectively guaranteed, it will directly affect the production efficiency and market competitiveness of the manufacturer. In the production process, crack failure is a common quality problem of aluminum alloy die-casting molds. This has not only attracted extensive attention from manufacturers, but has also been widely used to affect consumers. For this reason, it is particularly important to increase research on crack failure of aluminum alloy die-casting molds. The above content analyzes the causes of crack failure of aluminum alloy die-casting molds, and proposes preventive measures against cracking failure of aluminum alloy die-casting molds on this basis. It is hoped that it can bring certain reference value to relevant workers and promote the sustainable, rapid and healthy development of my country's aluminum alloy die-casting mold industry.

Articles Of The Same Type: The Reasons For Aluminum Die Casting Tooling Easy Cracking