In recent years, my country's automobile industry has achieved rapid development. With the increasing concern of environmental protection issues, energy-saving and emission-reduction technologies focusing on lightweighting have become one of the common issues in the automotive industry. As the material of choice for lightweight technology, aluminum alloy has been widely used in the automotive industry.

Die casting is one of the main forming methods of cast aluminum alloy. It has the characteristics of high material utilization, good surface forming quality and excellent mechanical properties. It occupies an important position in the production of aluminum alloy auto parts. Die-casting AlSi10MgMn alloy is Al-Si-Mg-Mn series high-strength and toughness aluminum alloy with good casting performance. Die-casting parts, especially high-vacuum die-casting parts, have excellent mechanical properties, and can be further strengthened by heat treatment. Therefore, this type of alloy has a thin wall and structure It has broad application prospects in the production of complex and load-bearing automobile structural parts or security parts.

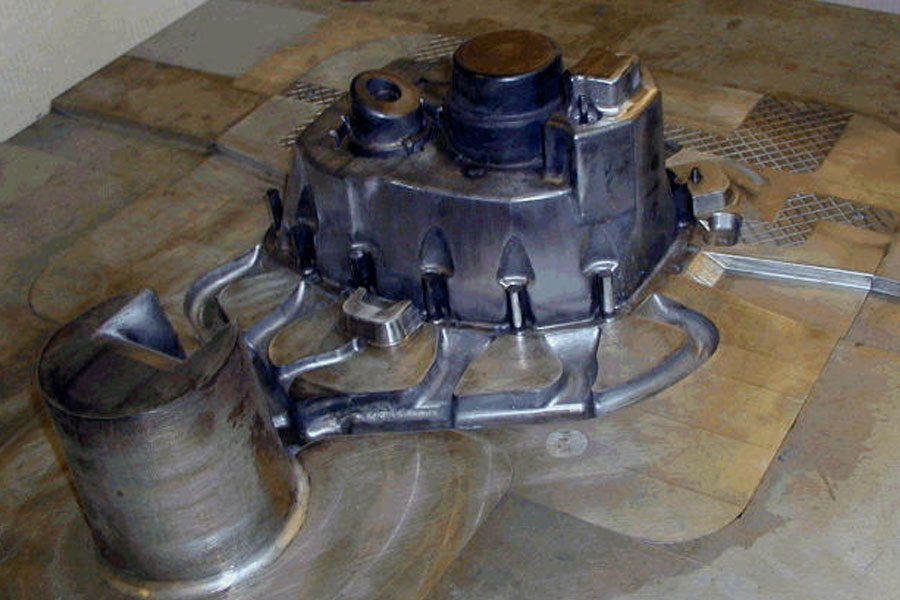

Based on the self-developed high-vacuum die-casting technology, this paper studies the influence of mold cavity vacuum on the structure and performance of castings when molten metal is filled; the high-vacuum die-casting technology is used to study the effects of artificial aging T1, high temperature solution treatment T5, and T6 respectively.

Optimization of the structure and properties of high-vacuum die-casting AlSi10MgMn; according to actual production needs, the influence of Mg content on the structure and properties of low-vacuum (ordinary) die-casting AlSi10MgMn was studied. Research indicates: