Die casting is a kind of casting technology m with a high degree of automation and capable of mass production of parts with complex shapes. The castings produced by it have the advantages of good compactness, high precision, less machining allowance, and excellent mechanical properties. It is used in automobiles and machinery. 1wl has been widely used in equipment and other fields. The casing shell is an important carrier for the installation of auto parts. Its wall thickness is relatively thin, but its mechanical properties, precision, and air tightness are required to be high, and mass production is required. Therefore, pressure casting is the best shell for manufacturing. s Choice.

This paper analyzes the structure of the casting, designs the casting system of the casting, and simulates it with PmCAST software. Through the analysis of the simulation results, the process is optimized to eliminate the defects such as shrinkage and porosity, so as to obtain A die-casting process that meets the technical requirements of the shell.

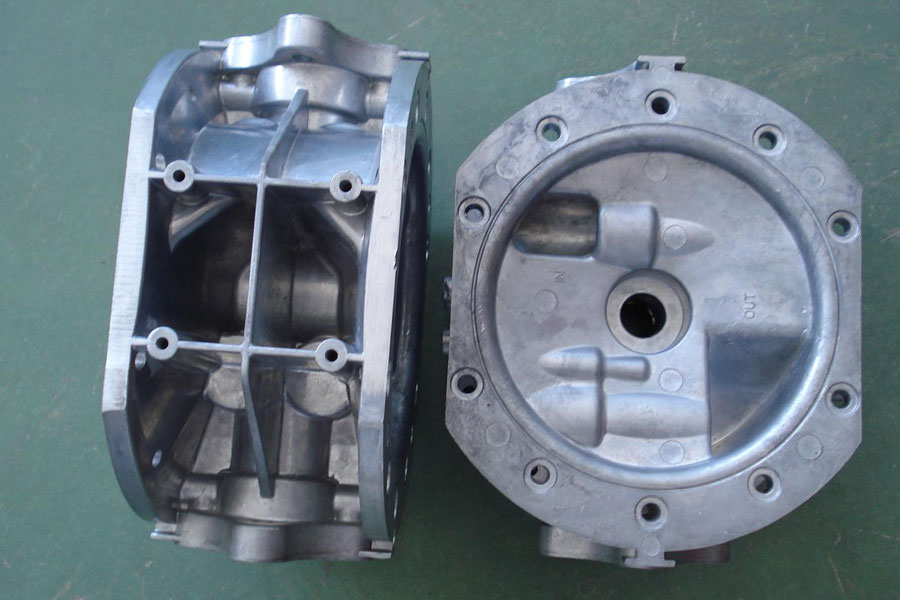

The casting under study is a casing for auto parts produced by a certain company. Its three-dimensional modeling diagram is shown in Figure I. The dark area is the machining surface of the casting, the machining allowance is 0.5 mm, and the outline size of the casting It is 103 mm x 98 mm x 89 mm, the casting volume is 234 108 mn r', the mass is 632 g, the thickest wall is 5.5 mm, the thinnest wall is 2.5 mm, and the average wall thickness is 3 mm. The casting material is Al-Si-Cu alloy YL113 with good fluidity, good air tightness, and high wear resistance. Its alloy composition is shown in Table lw. Castings are required to have a smooth surface, the draft angle should not exceed 1.5°, the casting shrinkage rate is 0.6%, and there should be no internal defects such as shrinkage holes and porosity.

In the mold design, the die casting process is the most important, which directly affects the quality of the casting, the production and Cnc machining cost, and the difficulty of mold manufacturing. The die casting process includes the selection of parting surface, the design of the gating system, the design of the overflow and exhaust system

Through process optimization, the castings are made free of shrinkage holes and porosity defects, and the optimized process is used for production verification. Through inspections, it is found that there are no shrinkage holes and shrinkage porosity defects inside the castings, and meet the technical requirements, which can be used to guide similar castings die-casting process design.