With the vigorous development of international aviation subcontracting products, the cooperation between customers has also become closer. The difficulty of parts processing has also changed from the initial single and simplified parts to the high-temperature alloy special-shaped parts and precision assembly parts of the composite process. Even more difficult multi-metal box shell parts. Due to the limitation of the weight of the aircraft, the materials of many shell parts are more inclined to aluminum alloy materials. For example, the material grades are L168, 6061, 2024 and other internationally used aluminum alloys. These types of materials can also achieve good corrosion resistance and wear resistance through early cold forming and late surface treatment. They are used in parts of various civil airliners such as Airbus, Boeing and even my country's C919. Today we are studying the processing method of aluminum alloy shell with porous, thin-walled die casting asymmetric structure.

1. Description Of Processing Difficulties

2. Processing Plan

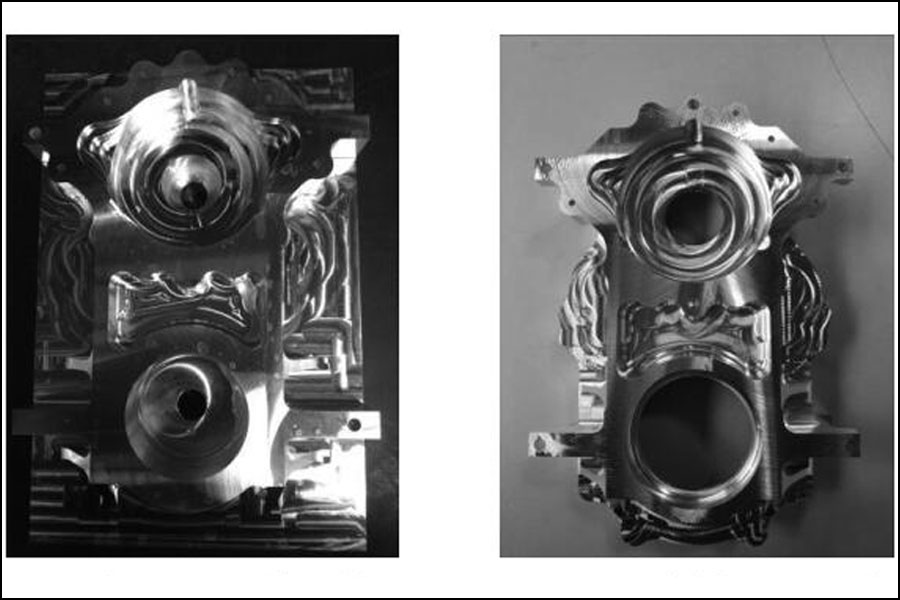

The processing of thin-walled porous parts can follow the general processing rules of shell parts, as shown in Figure 2. That is, rough machining, semi-finishing, and finishing; among them, the final requirements can be achieved through some finishing processes such as quilting, grinding, grinding, and fine boring according to the specific appearance, shape and size tolerance requirements of the part during finishing. . It can also be processed directly to the final size if the equipment accuracy level allows. Starting from raw materials, casting blanks or original aluminum blocks can be used to start processing according to customer requirements. The use of castings can save a lot of processing time in the preliminary rough machining.

3. Matters Needing Attention

4.The Conclusion

Through nearly one year of trial production and adjustment, a relatively complete set of processing technology routes have been explored, which provides valuable processing experience for the processing of this type of parts.