With the rapid development of power packs, electric vehicles, and subway motor manufacturing technologies, cast aluminum water-cooled frame structures are widely used in motor manufacturing. Green and environmentally friendly energy electric vehicle motors, high-speed EMU power pack generators, airport bus motors, and rail-use urban traffic permanent magnet traction motors mostly use cast aluminum water-cooled bases. The good heat dissipation effect of the water-cooled casting frame is the key to meeting the requirements of motor manufacturing. The main manufacturing process includes metal smelting technology, forming technology, assembly technology, processing technology and other aspects. Whether the structure of the cast aluminum water-cooled machine base is reasonable, and the quality of it directly affects the operating reliability, labor productivity and economic benefits of this type of motor. Application structure Reasonable cast aluminum water-cooled frame structure can improve the operating reliability of this type of motor frame, shorten the manufacturing cycle, save manufacturing costs, and improve labor productivity and economic benefits.

1. Current production technology status of water-cooled frame

1.1 Process method

The manufacturing methods of cast aluminum water-cooled bases in the same industry at home and abroad include: integral sand casting, split sand casting, extrusion molding, etc. The overall casting process is: mold core box manufacturing-sand mold sand core production-alloy smelting-box assembly-pouring-cleaning-finished product. The split casting process is: mold core box manufacturing-sand mold sand core manufacturing-alloy smelting-box assembly-pouring-cleaning-processing-welding-assembly to form a base blank. The extrusion molding process is: mold manufacturing-cast aluminum smelting-pouring aluminum ingots-high-pressure extrusion molding-welding-machine base blanks.

1.2 Shortcomings of traditional crafts and methods

The problem of integral casting cast aluminum water-cooled frame is low yield of the frame and long manufacturing cycle. The biggest problem is difficult to clean the water channel sand core and difficult to fix the water channel sand core; the structure of the split sand cast aluminum water-cooled frame has problems. The production process is cumbersome, the cycle is too long, the quality is difficult to control, and the inner and outer cylinders need to be pre-processed, and the end faces are sealed and welded, which is easy to leak after processing; the extruded cast aluminum water-cooled base structure: limited by the tonnage of the press, large The machine base cannot be realized, and there is the risk of water leakage due to the sealing and welding seam that needs to be processed. Often, the machine base leaks due to welding quality problems, which affects the machine base performance and even causes the motor to be scrapped.

2. Conception and Goal of the New Process Method

By analyzing the shortcomings of traditional process methods, a new process is proposed, the characteristics of which include:

3. The Specific Implementation Process Of The New Process

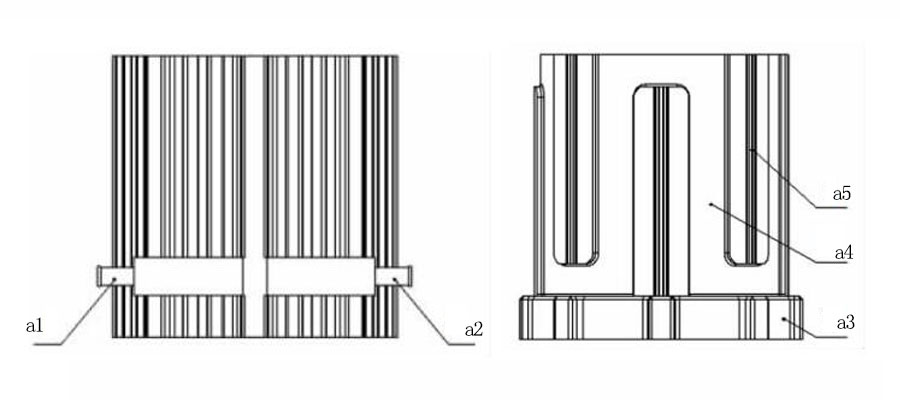

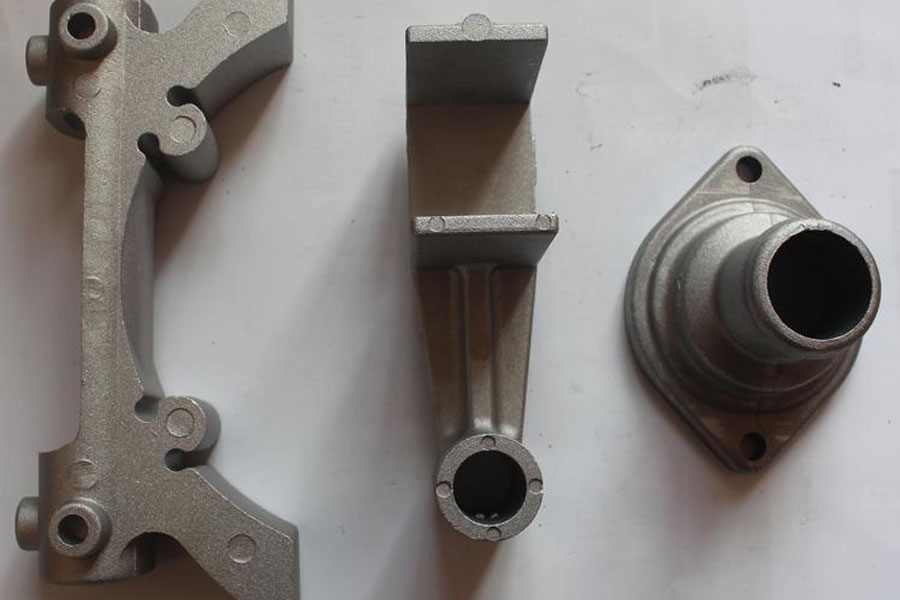

The process of the new die-casting process is: mold manufacturing-alloy smelting-die casting-hot sleeve-welding-base blank. The inner and outer cylinder water channels are cast into shape by die casting method, no processing is required. Make full use of the characteristics of die-casting, fast speed, high surface finish, using die-casting technology, die-casting into outer and inner cylinders. The W-shaped channel structure and guiding W groove are cast on the inner cylinder as shown in Figure 2; the outer cylinder is cast with a guiding and locking structure, the inner and outer cylinders are preheated at the same time, and then the inner and outer cylinders are heated as shown in Fig. 3.

The seal is welded into a base blank as shown in Figure 4. The advantages of the new process are:

4. Conclusion

The new production process of W-shaped water-cooled frame is a precedent in the domestic professional motor manufacturing industry. Based on the absorption of domestic and foreign cast aluminum frame manufacturing technology, combined with the casting structure, special process methods are used to realize the manufacturing of W-shaped cast aluminum water-cooled frame In the process, the characteristics of pressure casting are fully utilized, preheating interference sleeves are used, weld protection and water leakage prevention structure are cleverly arranged, and the manufacture of W-shaped cast aluminum water-cooled machine base is realized. Shorten the product development cycle, reduce the difficulty and labor intensity of motor production, simplify the manufacturing process of electrical machinery key components, improve the reliability of manufacturing and operation, and effectively control the cost of motor manufacturing.