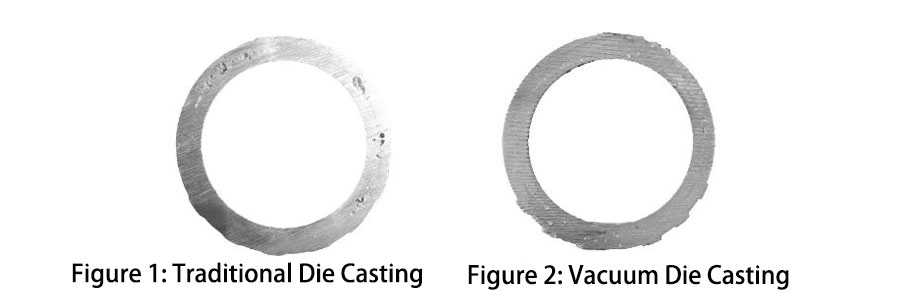

Compared with sand mold and gravity casting, the microstructure of traditional die castings is not satisfactory. The main reason is that the injection of high-speed metal flow at the gate is easier to contact the cavity than when the metal is slowly fed into the sand or metal mold cavity air. The focus of the vacuum die-casting process is to minimize this gas-liquid contact. Therefore, effectively exhausting the gas in the cavity is the key to the design of the vacuum die-casting mold.

For die-casting molds, there is no essential difference between traditional exhaust design and vacuum exhaust design. The only way to exhaust is that the former is passive exhaust, which uses metal flow to exhaust gas, which is the so-called positive pressure injection; the latter is active Exhaust, that is, by using a vacuum device to extract the gas in the cavity, it is also called negative pressure injection. As far as the exhaust effect is concerned, there is a big difference between the two. The correct vacuum exhaust application will greatly reduce the gas content in the cavity, thereby effectively improving the quality of the product.

This article combines the China Die Casting Cloud Computing Platform to discuss the location of the vacuum valve involved in the design of the vacuum mold scheme, focusing on whether the vacuum valve should be farther away from the inner gate or closer?

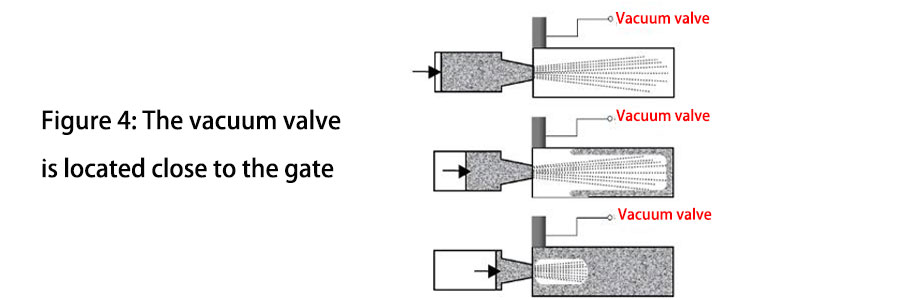

In the process of vacuum die-casting mold design, the position of the vacuum valve should be able to keep the vacuum valve open for a long time, so as to extract as much gas as possible.

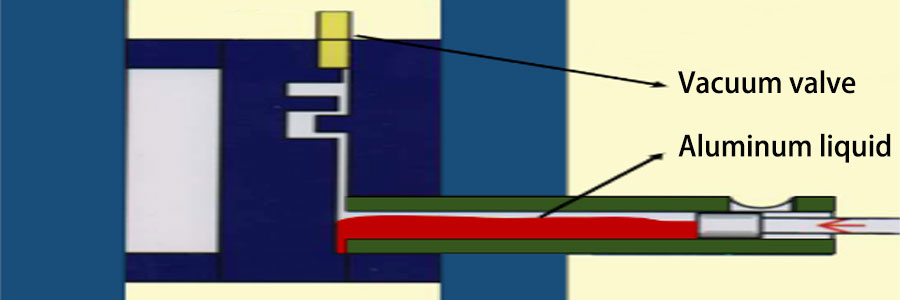

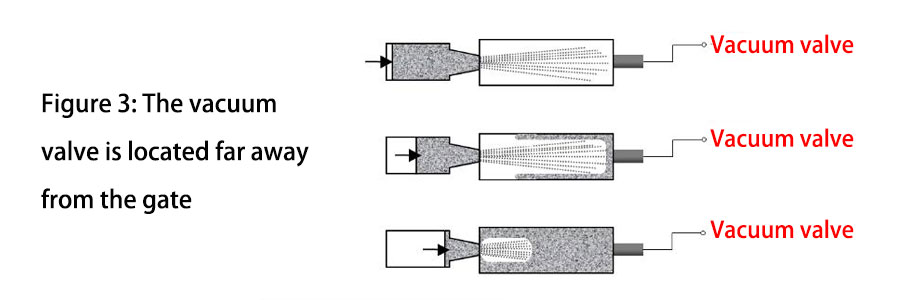

The vacuum valve must be set at the position where the alloy melt is filled last, but this position may be counterintuitive, as shown in Figure 3: Like conventional die-casting, vacuum die-casting presents an atomized flow. If the vacuum valve is set at the farthest from the gate Position, the vacuum valve may be closed earlier in the cavity filling process.

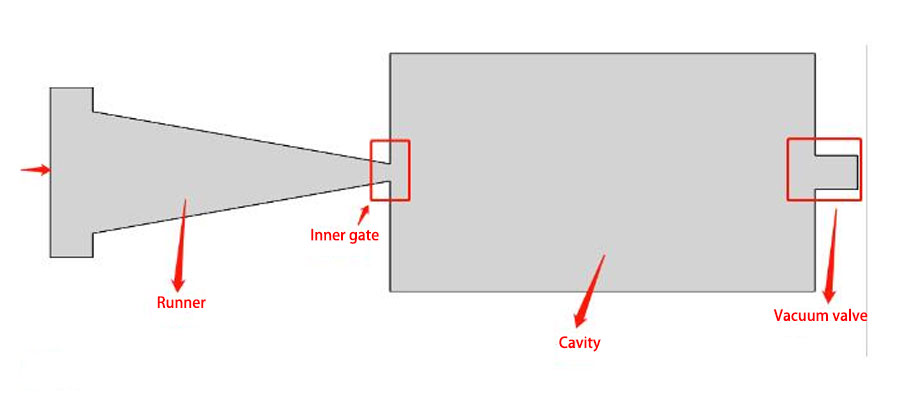

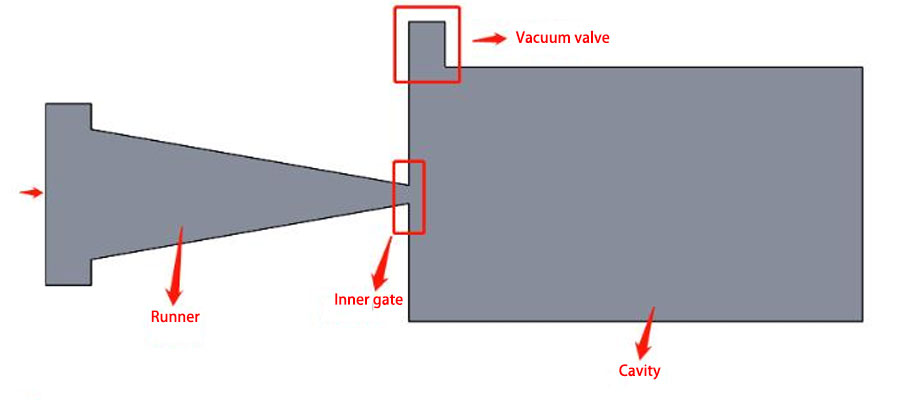

In order to vividly illustrate the above point of view, two targeted models are hereby designed, as shown in Figures 5 and 6 below. Die-casting mold filling simulation is carried out through the Chinese die-casting cloud computing platform to observe the flow of alloy melt in the cavity and understand intuitively The difference between the two vacuum valve positions in the actual die-casting process.