Human Factors

Factors of equipment, mould and tooling

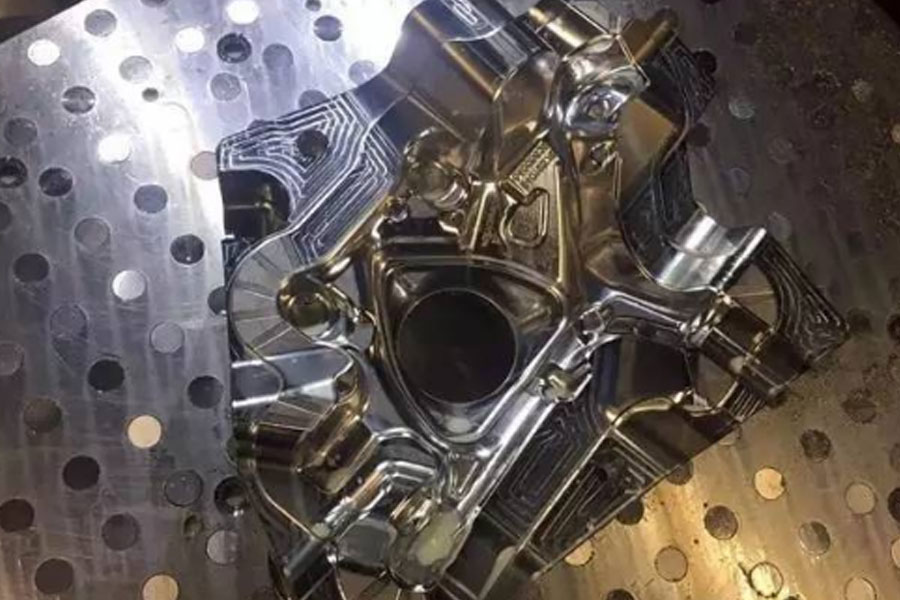

The factors of equipment, mould and tooling mainly involve mould quality and equipment performance.

Is the die-casting mold design reasonable? Will it cause pores?

Reasons for die casting molds:

2.2 Is the exhaust hole blocked and the air cannot be discharged?

2.3 Is there too much lubricant on the punch, or burned corners? This is also one of the sources of gas.

2.4 Does the gate position and diversion shape first seal the overflow system on the parting surface?

2.5 Is the position of the inner gate unreasonable? After passing through the inner gate, the metal immediately hits the shaped wall and generates eddy currents, and the gas is drawn into the metal flow?

2.6 The position of the exhaust duct is incorrect, causing poor exhaust conditions?

2.7 Is the area of the spillway large enough? Is it blocked and is it located at the last filling place? Is the mold venting part cleaned frequently? To avoid losing the venting effect due to clogging of the release agent

2.8 Is the mold temperature too low?

2.9 Is the runner turning round enough? Increase the inner gate appropriately?

2.10 Are there any vent plugs in the deep cavity, or use inlays to increase venting?

2.11 Is there any part that is difficult to exhaust due to unreasonable die-casting design?

2.12 Is the total cross-sectional area of the overflow less than 60% of the total cross-sectional area of the inner gate, and the slag removal effect is poor?

2.13 Is there a way to increase the thickness of the inner gate to reduce the filling speed under good molding conditions?

2.14 Is the gate speed too high, the flow dissipation is excessive, and the metal flow is seriously involved in gas?

2.15 Is the cross-sectional area of the inner gate too small and serious jetting?

2.16 Whether to fill in order to facilitate the discharge of cavity gas. Is there sufficient length for sprue and runner?

Three Material Factors

Four Die-Casting Parameters, Operating Process Factors

Five Environmental Factors

Is the air humidity in the die-casting environment high?

Under normal circumstances, the hydrogen content in the surrounding air is not much. But if the relative humidity in the air is high, it will increase the solubility of the gas in the molten aluminum and form seasonal pores. For example, in the rainy season, due to the high humidity of the air, the phenomenon of pinholes during aluminum alloy melting is more serious. Of course, the air humidity is high. At this time, aluminum alloy ingots, smelting equipment, tools, etc. will also increase the amount of surface moisture adsorption due to humid air, so more attention should be paid to adopting strong preheating and drying protective measures to reduce the generation of pores.