Die-casting machine is an important basic technical equipment in die-casting production, which has a direct impact on the quality, production efficiency, operating cost, labor intensity, environment, and hygiene of die-casting parts. Therefore, there should be a clearer understanding of the die-casting machine, so that the die-casting machine can be used in a standardized and reasonable manner to ensure the smooth progress of the die-casting production and increase labor productivity.

Classification Of Die Casting Machine

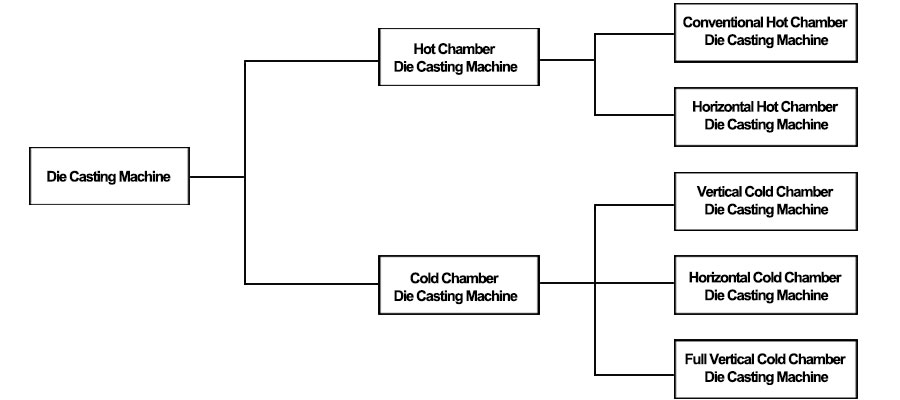

There are many classification methods for die-casting machines. According to the scope of use, they are divided into general die-casting machines and special-purpose die-casting machines; according to the clamping force, they are divided into small machines (≤4 000 kN), medium machines (4 000~10 000 kN) and large machines. Machine (≥10 000 kN); Generally, it is mainly classified according to the machine structure and the position of the injection chamber (hereinafter referred to as the pressure chamber) and its working conditions. The names of various types of die-casting machines are shown in Figure 1.

Fig.1 Classification of die casting machine

The horizontal hot-chamber die-casting machine in Figure 1 is placed horizontally. It was first developed by Harvill Company in the United States in 1981, and it was advertised in 1982. In 1983, it was exhibited at the 12th International Die-casting Conference and Exhibition in the United States. Horizontal hot chamber injection mechanism. Due to various reasons, this kind of machine has not yet been popularized, so I will not introduce it for the time being.

The Composition Of The Die Casting Machine

How The Die Casting Machine Works

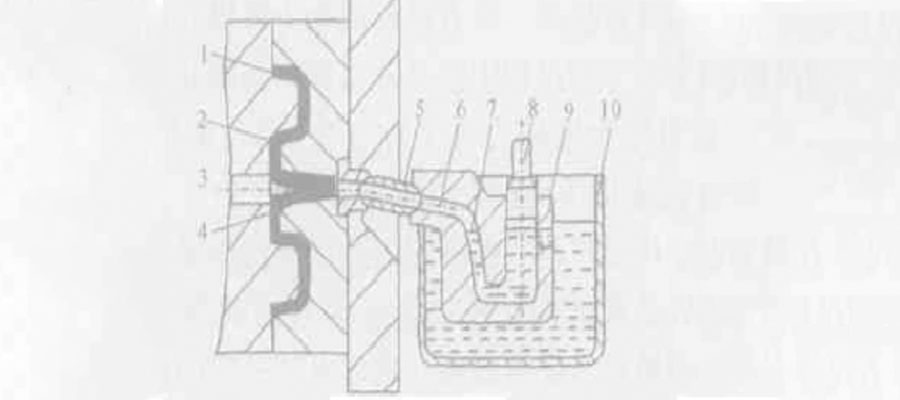

Hot chamber die casting machine

The normal working mode of hot chamber die casting machine is shown in Figure 2. The furnace 10 of the hot chamber die casting machine is placed in the machine. Pouring into the furnace, the pouring pot 9 with the pressure chamber and the gooseneck channel and the injection punch 8 are all immersed in the molten metal 7. The opening and closing actions of the mold move horizontally. After the mold is opened, the die casting remains in the movable mold. The working steps are as follows:

Cold Chamber Die Casting Machine

The main engine of the cold chamber die casting machine is separated from the furnace, the furnace is placed on the side, and the molten metal is transferred from the furnace to the press chamber of the main engine. The furnace is usually only guaranteed.Because it is used for warming, it is often called a holding furnace; only when the number of machines is small or small batch production, the holding furnace also serves as a melting point. The cold chamber die casting machine is divided into vertical cold chamber, horizontal cold chamber and full vertical cold chamber.

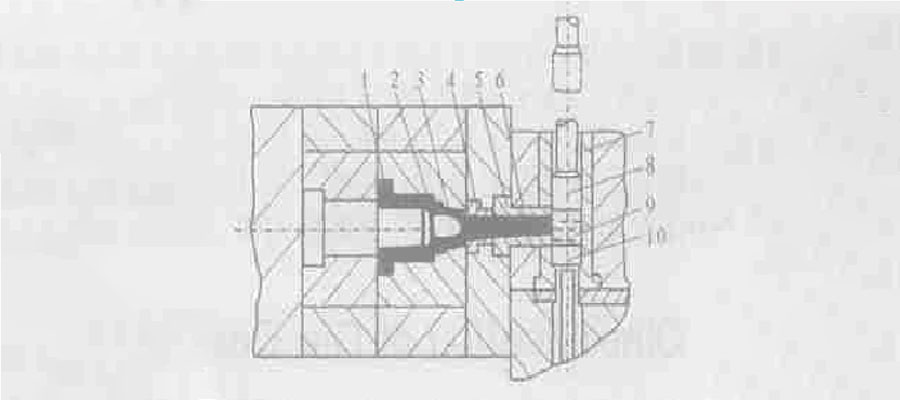

Working mode of vertical cold chamber die casting machine

The working mode of the vertical cold chamber die casting machine is shown in Figure 3. The pressure chamber 7 is placed vertically, and the upper punch 8 is above the pressure chamber (the position above the figure), and the lower punch 10 is located at the place where the nozzle 5 orifice is blocked, so as to prevent molten metal from pouring into the pressure chamber and flowing into the nozzle hole by itself. The opening and closing of the mold is horizontal.After moving and opening the mold, the die casting remains in the movable mold. The working steps are as follows:

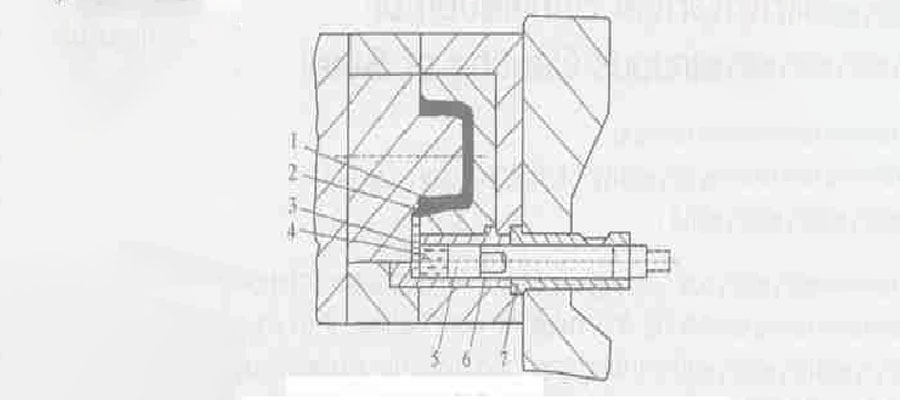

Working mode of horizontal cold chamber die casting machine

The working mode of the horizontal cold chamber die casting machine is shown in Figure 4. The pressure chamber 7 is placed horizontally, and the injection punch 5 is at the dotted line at the rightmost end of the pressure chamber. The opening and closing movements of the mold move horizontally. After the mold is opened, the die-casting part remains in the movable mold. The working steps are as follows:

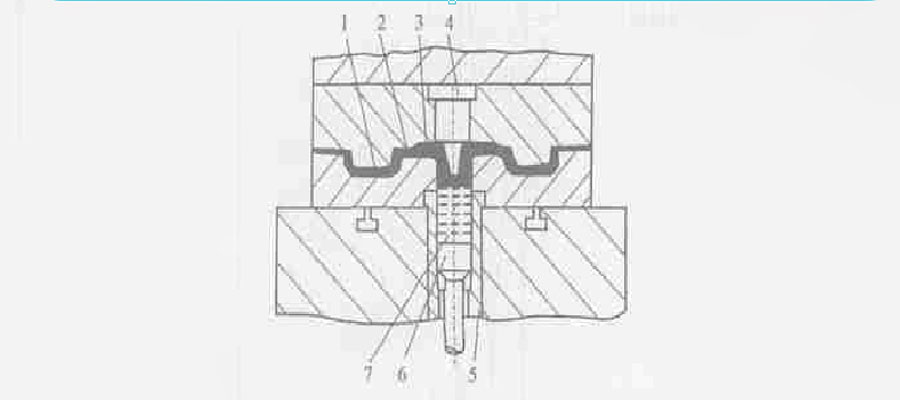

Working mode of full vertical cold chamber die casting machine

The working mode of the full vertical cold chamber die casting machine is shown in Figure 5. The pressure chamber 5 is placed vertically at the lower part of the machine, and the opening and closing of the mold move up and down, so it is called a full vertical die-casting machine. Usually the movable mold of the mold is fixed on After the mold is opened, the die-casting part remains in the movable mold. The working steps are as follows:

Relevant standards of Chinese die casting machine

In order to further promote the development of my country's die-casting machine production, the relevant departments of my country's machinery industry promulgated the die-casting machine parameter standards in 1980 and revised it in 1990. In the same year, standards for the accuracy and technical conditions of the die-casting machine were also promulgated, which provided a reference for the design, manufacture, and acceptance of the die-casting machine. Since then, it has been revised several times to make it more complete and more practical. The machinery industry standards for die-casting machines and their serial numbers promulgated after the revision in 2000 are as follows. Die-casting machine parameters (JB/T 8083 -2000) The standard defines the parameters of the die-casting machine. The die-casting machine is divided into three types: horizontal cold-chamber die-casting machine, vertical cold-chamber die-casting machine and hot-chamber die-casting machine. The main parameters and basic parameter values of the three types are listed in the appendix.