Engineering

Bringing Engineering Designs to Life - Engineering Services In China

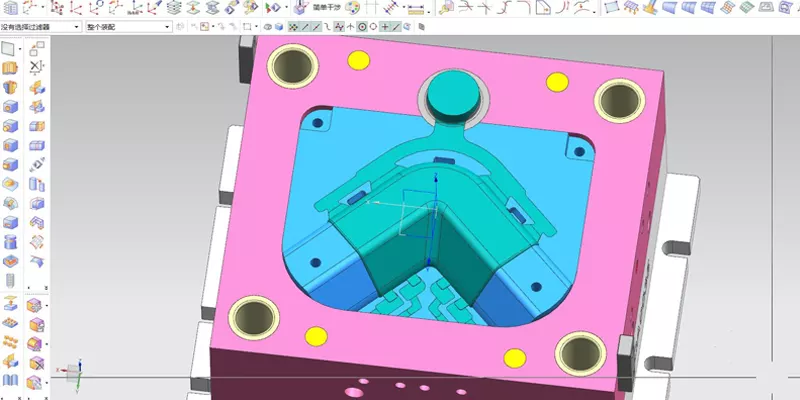

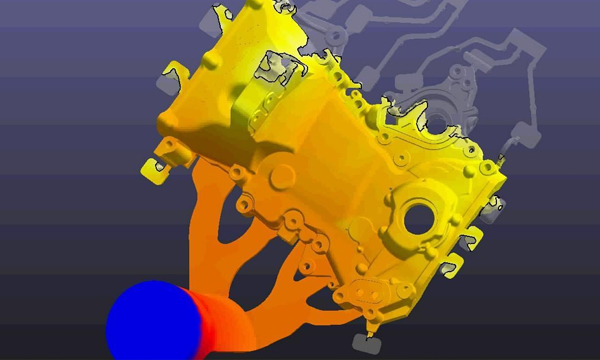

The Advantage Of Die Casting Engineering

The functions of die casting engineering can be summarized as follows:

- – Excellent dimensional accuracy (dependent on casting material, but typically 0.1 mm for the first 2.5 cm (0.004 inch for the first inch) and 0.02 mm for each additional centimeter (0.002 inch for each additional inch).

- – Smooth cast surfaces (Ra 1–2.5 micrometres or 0.04–0.10 thou rms).

- – Thinner walls can be cast as compared to sand and permanent mold casting (approximately 0.75 mm or 0.030 in).

- – Inserts can be cast-in (such as threaded inserts, heating elements, and high strength bearing surfaces).

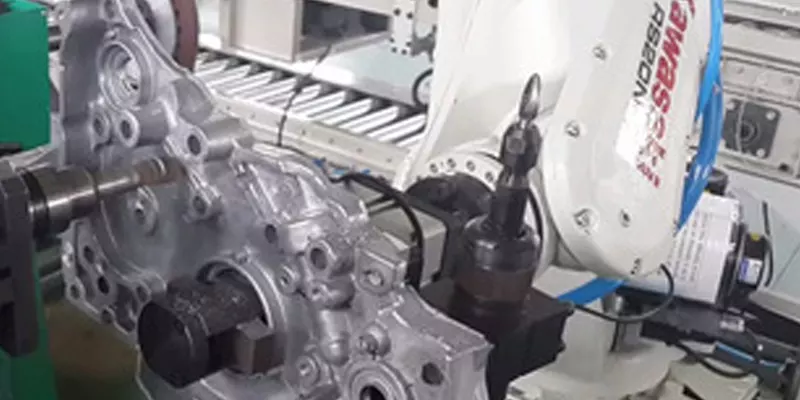

- – Reduces or eliminates secondary machining operations.

- – Rapid production rates.

- – Casting tensile strength as high as 415 megapascals (60 ksi).

- – Casting of low fluidity metals.

Different Types of Die Casting Engineering– Supplement Services Available at Minghe

We provide a wide range of engineering solutions for die casting production, including value engineering, metallurgical engineering, target price discussion, life cycle cost calculation and value analysis. With the help of our engineering professionals, you will get a guarantee of top products, which only we can provide here. If you want to communicate with one of our engineering professionals, please contact us online.

Upload Your Profile

Trimming

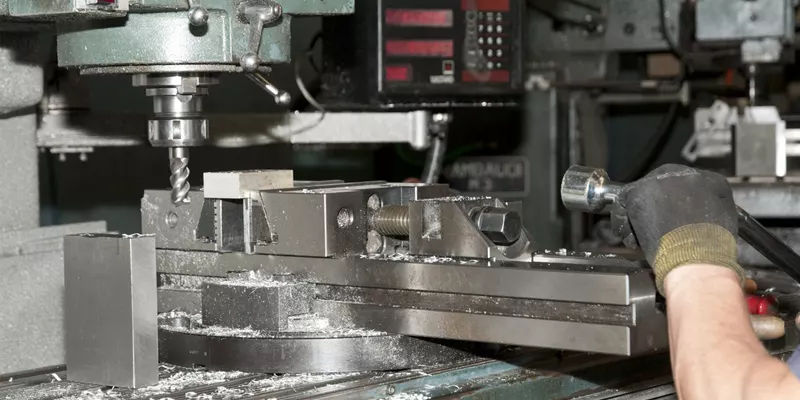

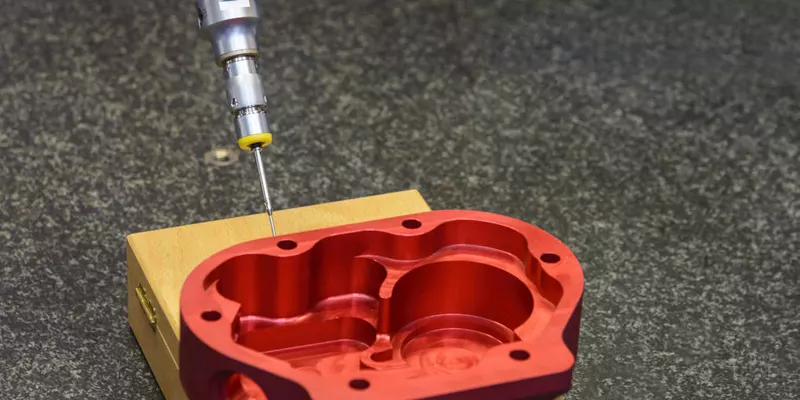

Drilling & Tapping

Deburring Surface

Final Inspection

Packing And Shipping

After Sales and Return