CNC Machining

Online Quote CNC Machining Services

Minghe offers in-house CNC machining as a complement to our die casting services. These CNC machines use a tailored approach to manufacture custom-made parts that are ready for product assembly

Want to shorten production cycle and reduce cost of your machinery components? Integrated multiple advanced technologies, CNC Machining Services can simplify the manufacturing process and speed up large batch production of machined components, as well as achieve a higher level of accuracy. Minghe provides rapid online CNC machining according to customer requirements. Send your CAD files or inquiry to us, fast free CNC components quote will be back.

Whether it is high-speed prototype or mass-produced part, we have the right CNC machining options to meet the needs of both metal and casting parts. Get your projects into machining in the shortest time.

Why Choose China Cnc Machining Services?

Many customers choose China's services, but only care about two points: low prices and quality to meet their needs. But with the further development of internationalization, price is no longer a development element for evaluating a qualified supplier.

Although Japan and Germany have more advanced technologies in terms of innovation and design capabilities, you can get a comprehensive capability by choosing a Chinese CNC processing service provider.

At Minghe, we pay more attention to honesty and quality. CNC machining is just a small category of our company, we pay more attention to mature and long-term cooperation.

Minghe gives you production capacity and diverse machining capabilities for EDM parts with even the tightest tolerances, most complex internal geometries, or augmented process requirements.

China Minghe Surface Finishes

You can choose a wide selection of metal surface finishing services after machining at Minghe CNC machining or die casting manufacturer to improve the parts appearance, surface smoothness, corrosion resistance and other performance of your CNC machined parts.

|

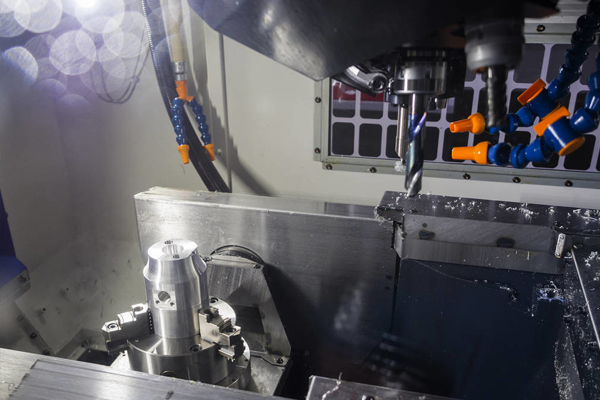

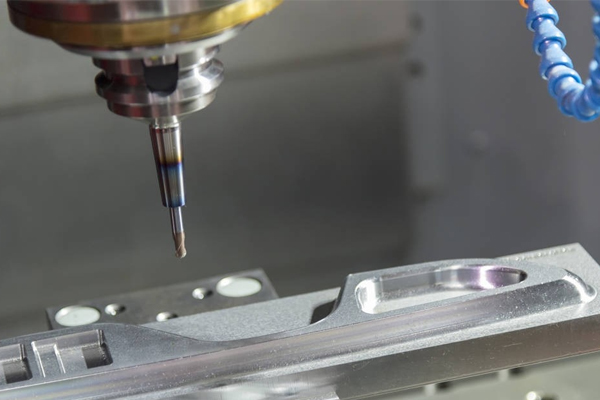

Cnc Milling

|

| CNC milling used to process prismatic parts. |

|

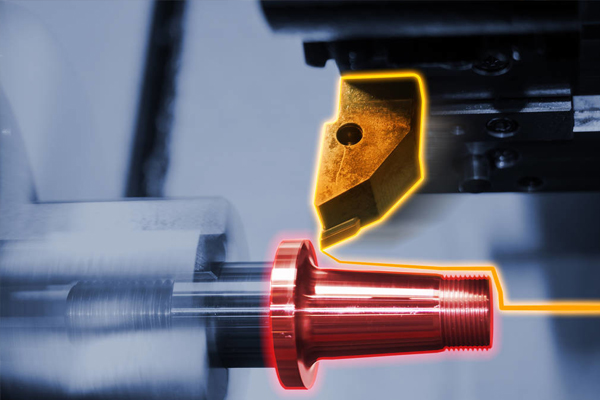

Cnc Turning

|

| CNC Turning mainly uses tooling to turn a rotating workpiece. |

|

Swiss Machining

|

| It will be used to machine small parts in bars. |

|

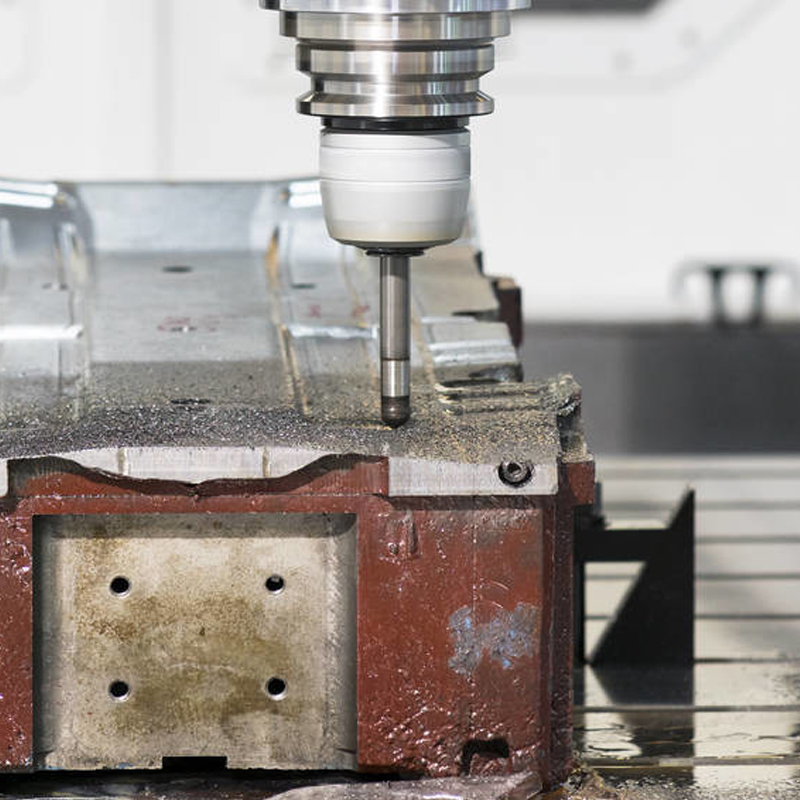

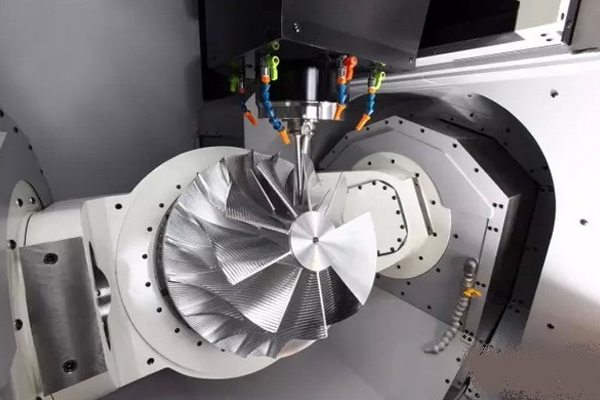

5 Axis Machining

|

| Often used to process complex parts. |

|

Vertical Machining

|

| Suitable Machining for boards, discs, molds and small shells. |

|

Horizontal Machining

|

| Realized Milling by the spindle horizontal layout mechanism. |

China Minghe CNC Machining Materials

Minghe CNC Machining services working with Conventional Alloy, Super Alloy and plastic.

|

Conventional Alloy

|

|

|

Super Alloy

|

|

|

Plastic Machining

|

|

China Minghe Surface Finishes

You can choose a wide selection of metal surface finishing services after machining at Minghe CNC machining or die casting manufacturer to improve the parts appearance, surface smoothness, corrosion resistance and other performance of your CNC machined parts.

| Painting ▶ |

| Passivation ▶ |

| Electroplating/Plating ▶ |

| Powder coating/Powder coat ▶ |

| Anodizing/Anodized ▶ |

| Polishing ▶ |

| Black oxide ▶ |

| Conversion coating ▶ |

| Bead blasting/Bead blast ▶ |

| Abrasive blasting/sandblasting ▶ |

| Thermal Spraying ▶ |

| Surface Hardening ▶ |

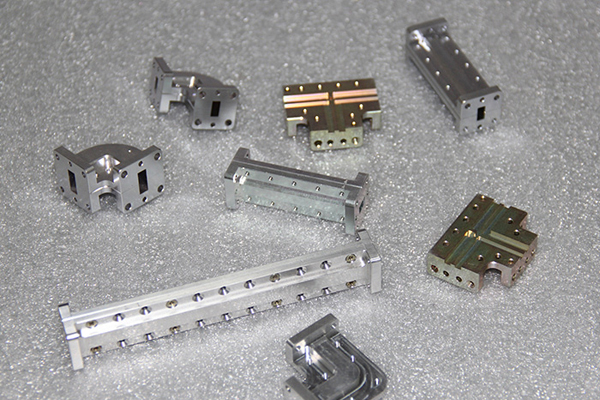

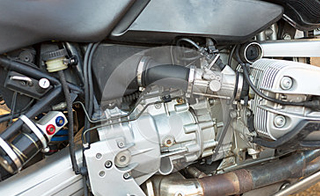

Applications of MINGHE Die Casting Services

Die Casting parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. Minghe is an accomplished casting supplier that engaged in a broad range of die casting applications.

Our manufacturing parts are suitable for following industries:

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

INDUSTRY

The Advantages of Minghe CNC Machining Services

- Efficient CNC machining china factory for mass production rapid prototyping service

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

- High customer satisfaction and loyalty

- Rich design and manufacturing experience

- Automation is increased.

- Minimal Errors

- Our Services is cost effective.

- Volume: 1-20+ Parts

- Quoting: Within 24 hours

- Lead Time: In as fast as 3 days

- Materials: metals and plastics

- Part size: Ranging from 10 in. x 7 in. x 3.75 in. to 22 in. x 14 in. x 1.25 in

- Standard Tolerances: +/- 0.1mm