CASTING

|

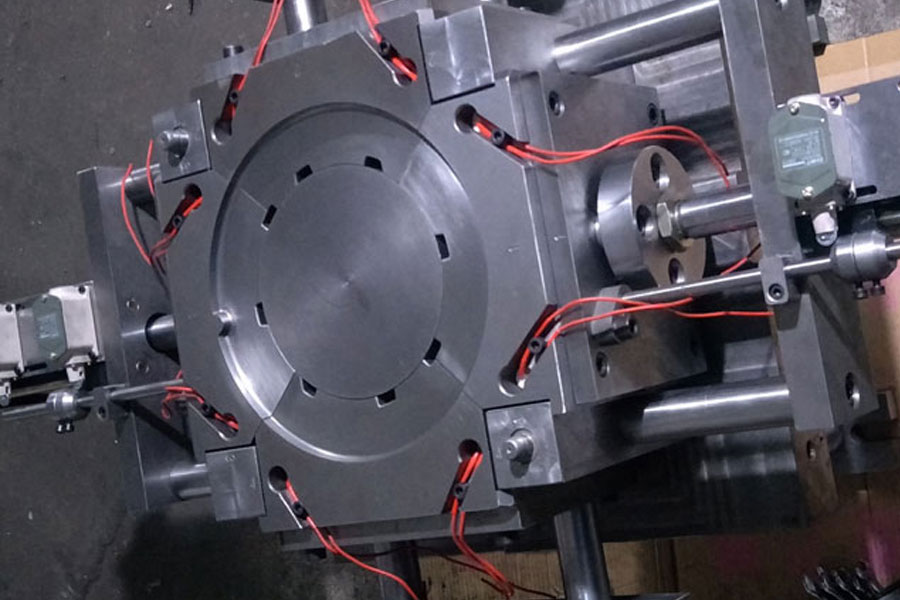

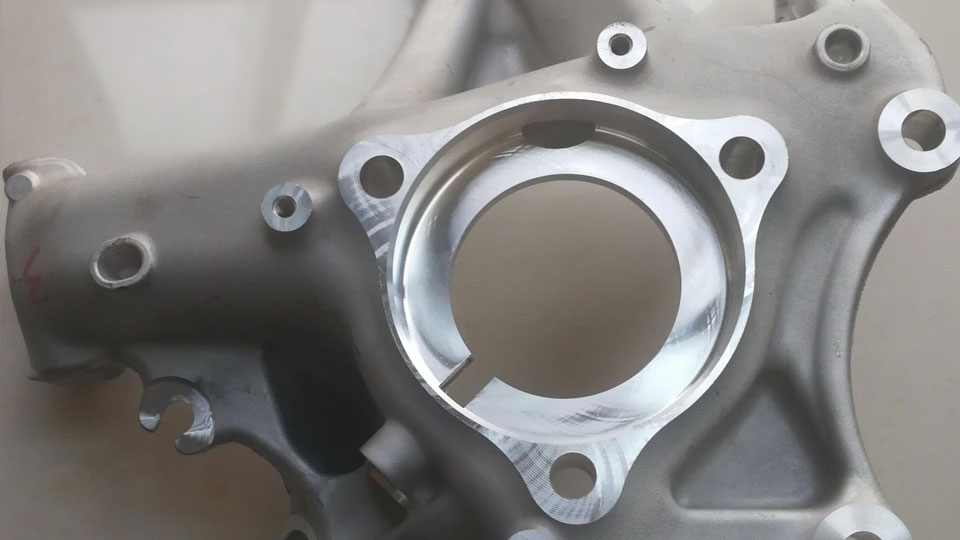

Die CastingDie casting is a manufacturing process in which molten metal is poured or forced into steel molds. |

|

Investment CastingInvestment casting provides the ultimate design flexibility for highly complex parts made from a large choice of alloys. |

|

Sand CastingSand casting is a process of using sand as the primary material to mold various metallic products. |

|

Lost Foam CastingLost foam casting is to combine paraffin wax or foam models similar to the casting size and shape into model clusters. |

|

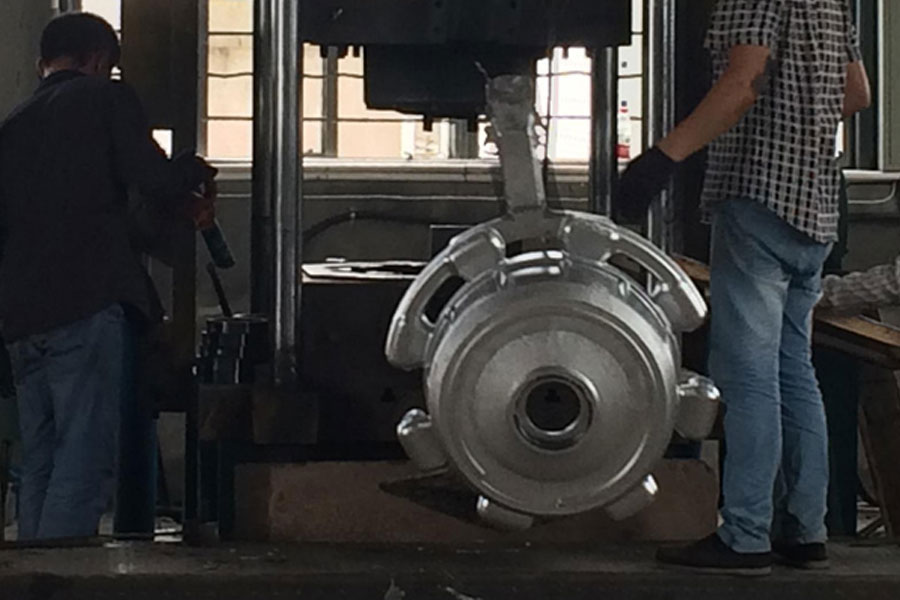

Centrifugal CastingCentrifugal casting when the rotation axis of the mold is in a vertical state is called vertical centrifugal casting. |

|

Low Pressure CastingThis casting method has good feeding and dense structure, easy to cast large thin-walled complex castings. |

|

Permanent Mold CastingPermanent Mold Casting have a long life and high production efficiency, not only have good dimensional accuracy and smooth surface |

|

Vacuum CastingVacuum Casting is a casting process in which metal is smelted, poured and crystallized in a vacuum chamber |

|

Gravity CastingMinghe Gravity Casting services can meet the needs of customers in the production of high-volume & low-cost casting parts. |

|

Aluminium CastingMinghe Casting offers a range of Die Casting Aluminum process to produce precise and complex Aluminum die casting parts with high dimensional tolerances. |

|

Zinc CastingMinghe is the China top die casting zinc parts manufacturer, offering a wide range zinc precision custom components die casting parts for various applications. |

|

Magnesium CastingMinghe Casting offers a range of magnesium die casting process to produce precise and complex magnesium die casting parts with high dimensional tolerances. |

|

Aluminum Investment CastingMinghe is of China top manufacturer of custom aluminum investment casting parts and components with aluminum investment casting parts machining services,Mould Making, design and engineering services are available. |

|

Aluminum Sand CastingMinghe Casting offering custom aluminum sand casting services and precision aluminum sand casting parts,mould making, cnc machining parts, mass manufacturing, surface treatment, etc. |

|

More Casting MaterialMinghe Die Casting Company is the China top die casting parts manufacturer, offering a wide range material precision casting components mass manufacturing metal parts for various applications. |

|

Brass CastingCopper alloy with zinc as the main alloying element is usually called brass. The copper-zinc binary alloy is called ordinary brass, and the ternary, quaternary or multi-element brass formed by adding a small amount of other elements to the copper-zinc alloy is called special brass. Casting brass is a casting alloy based on Cu-Zn binary alloy. Its crystallization temperature interval is small and its casting performance is better. Compared with tin bronze, cast brass has higher mechanical properties. In addition, because brass contains a large amount of zinc, the cost is lower. These are the reasons why cast brass is widely used. |

|

Iron CastingThe molten iron, after being heated to the desired temperature, is poured into the casting mold through a pouring system. The liquid iron flows into the mold cavity, filling it under the influence of gravity or external pressure. Once the mold is completely filled, the casting is allowed to cool and solidify within the cavity. After cooling, the casting is removed from the mold, and any surface defects such as shrinkage, flow marks, or rough edges are eliminated through finishing processes. Preheating of the mold is often performed to reduce thermal shock and ensure better surface quality of the final iron casting. |

|

Steel CastingCast steel can be divided into cast alloy steel and cast carbon steel according to its chemical composition. Steel casting refers to a process dedicated to manufacturing steel castings. Cast steel should be used when the strength of the casting is relatively high and the use of cast iron cannot meet the requirements. However, the liquidity of cast steel is not as good as cast iron, so the thickness of the casting structure should not be too small, and the shape should not be too complicated. When the silicon content is controlled at the upper limit, the fluidity of molten steel can be improved. |

|

Bronze CastingBronze originally refers to copper-tin alloys, but it is customary in the industry to call copper alloys containing aluminum, silicon, lead, beryllium, manganese, etc. also bronze, so bronze actually includes tin bronze, aluminum bronze, aluminum bronze, beryllium bronze, Silicon bronze, lead bronze, etc. Casting tin bronze contains high tin content, while processing tin bronze contains low tin content. The tin content of tin bronze used for pressure processing is less than 6% to 7%, and the tin content of cast tin bronze is 10% to 14%. |